High precision and high surface quality parts at SuNPe

- designer:

- Types:

- Craft:

- time:2023-03-21 09:31:28

- Pageviews: time

- Service Content:At SuNPe, we provide one-stop service for the parts in both high accuracy and high surface quality requirements. These parts are in very tight tolerances and very smooth surface finish, they need to make with advanced manufacturing techniques, like CNC milling to ensure that they meet exacting specifications. In addition to accuracy, these parts have a very smooth surface finish after the machining. While these Auto Equipment parts are required an attractive appearance. Various kinds of surface finish services on SuNPe can help it.

- Preview:View

At SuNPe, we provide one-stop service for the parts in both high accuracy and high surface quality requirements. These parts are in very tight tolerances and very smooth surface finish, they need to make with advanced manufacturing techniques, like CNC mi

High precision and high surface quality parts at SuNPe

Overview:

At SuNPe, we provide one-stop service for the parts in both high accuracy and high surface quality requirements. These parts are in very tight tolerances and very smooth surface finish, they need to make with advanced manufacturing techniques, like CNC mi...

At SuNPe, we provide one-stop service for the parts in both high precision and high surface quality requirements. These parts are in very tight tolerances and very smooth surface finish, they need to make with advanced manufacturing techniques, like CNC milling to ensure that they meet exacting specifications.

Normally, these parts are widely used in industrial applications such as aerospace, automotive, and medical equipment etc, where accuracy, consistency, and reliability are of utmost importance. A special Auto Equipment part case in SuNPe can help you learn more about it, let’s follow me.

Strict quality control measures are implemented to ensure that each part is within the specifications, our QC team will verify the deformation and the dimensions of the parts via the CMM measurement.

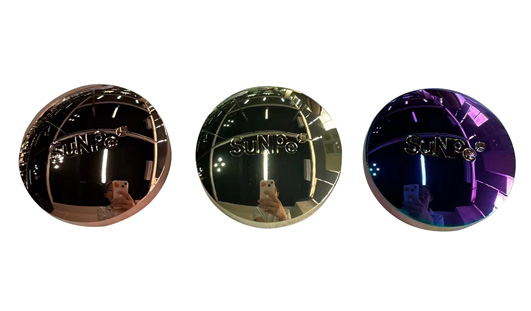

We do the fine sandblasting and color anodized finish to reach the matt and colorful effect. Doing anodized finish can not only improve the corrosion resistance, but also can play a good decorative role, a variety of brightly colored surfaces can be obtained by dyeing. We machine the lines and circled features and remove the sandblasting coating of the ‘SuNPe’ logo by 5-axis CNC machining after the sandblasting, then do the polishing to make these small features in glossy.

For the specific features or positions without anodizing , they can be removed the anodized coating by 3-axis CNC machining or grinding by hand on these areas. We also can do the color ink filling and laser engraving the text on the designated position make the parts becoming more pleasing to the eye.

In summary, high precision and high surface quality parts are critical components that play an important role in a wide range of industries. They are made with advanced manufacturing techniques and materials, and require skilled technicians and strict quality control measures. These parts ensure the products in which they are used are accurate, safe, and reliable.

Pls contact us for any interest.

Normally, these parts are widely used in industrial applications such as aerospace, automotive, and medical equipment etc, where accuracy, consistency, and reliability are of utmost importance. A special Auto Equipment part case in SuNPe can help you learn more about it, let’s follow me.

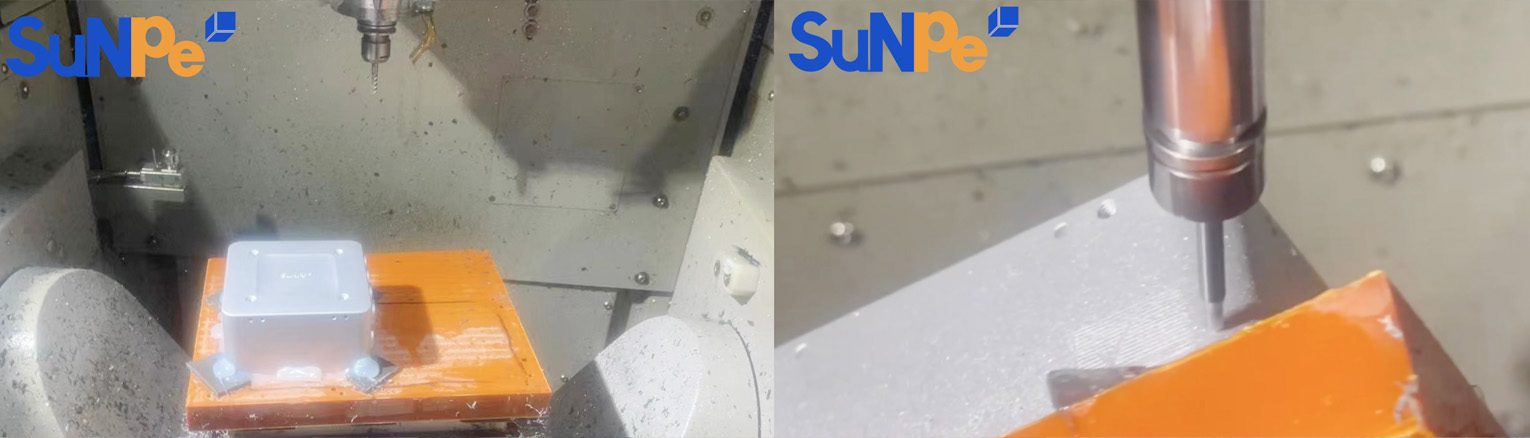

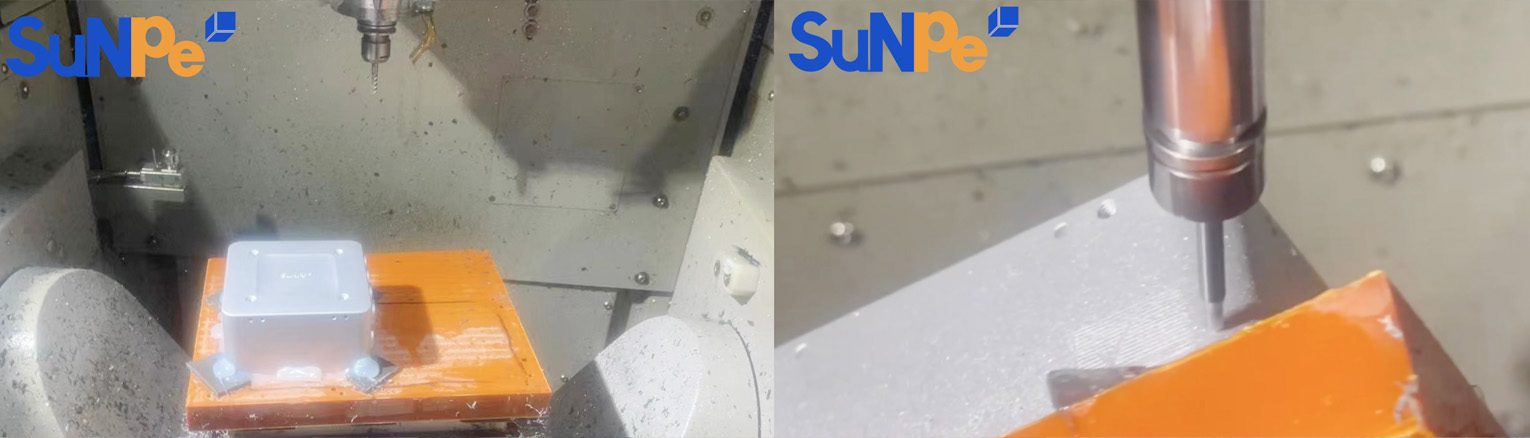

How does SuNPe protect the parts from deformation during the machining, and ensure the assembly among the parts?

These assembly parts are in aluminum material and hollow structure, the wall thickness is 2.2mm only, the material is soft and the thickness is thin, it would be easy to deform if machining directly. These parts are also in very tight tolerances +/-0.025mm, meaning that even the slightest variation in dimensions can result in their failure. Our professional technicians with in-depth knowledge of materials and manufacturing processes use the specialized CNC machine and cutter to make the parts to meet the strict specifications, in the meanwhile we also will follow the tolerance requirement in the drawing provided by our customer technically during the programming.Strict quality control measures are implemented to ensure that each part is within the specifications, our QC team will verify the deformation and the dimensions of the parts via the CMM measurement.

How to achieve the various kinds of surface appearance on a part?

In addition to accuracy, these parts have a very smooth surface finish after the machining. While these Auto Equipment parts are required an attractive appearance. Various kinds of surface finish services on SuNPe can help it.We do the fine sandblasting and color anodized finish to reach the matt and colorful effect. Doing anodized finish can not only improve the corrosion resistance, but also can play a good decorative role, a variety of brightly colored surfaces can be obtained by dyeing. We machine the lines and circled features and remove the sandblasting coating of the ‘SuNPe’ logo by 5-axis CNC machining after the sandblasting, then do the polishing to make these small features in glossy.

For the specific features or positions without anodizing , they can be removed the anodized coating by 3-axis CNC machining or grinding by hand on these areas. We also can do the color ink filling and laser engraving the text on the designated position make the parts becoming more pleasing to the eye.

In summary, high precision and high surface quality parts are critical components that play an important role in a wide range of industries. They are made with advanced manufacturing techniques and materials, and require skilled technicians and strict quality control measures. These parts ensure the products in which they are used are accurate, safe, and reliable.

Pls contact us for any interest.