How we machine tiny slots of clear part and keep good surface roughness.

- designer:

- Types:

- Craft:

- time:2024-04-17 09:27:14

- Pageviews: time

- Service Content:We have a rich expensive to machine the tiny feature, here is a case showing how we machine tiny slots of clear part and keep good surface roughness without sanding or polishing.

- Preview:View

We have a rich expensive to machine the tiny feature, here is a case showing how we machine tiny slots of clear part and keep good surface roughness without sanding or polishing.

How we machine tiny slots of clear part and keep good surface roughness.

Overview:

We have a rich expensive to machine the tiny feature, here is a case showing how we machine tiny slots of clear part and keep good surface roughness without sanding or polishing....

Due to the nature of the CNC machining process, minor tool marks will always be evident on as-machined parts, and one of the challenges of machining is maintaining a smooth surface finish on the part, especially on some small feature that unable to apply the surface finish. We have a rich expensive to machine the tiny feature, here is a case showing how we machine tiny slots of clear part and keep good surface roughness without sanding or polishing.

Material: PMMA

Surface finish: Deburred

Lead time: 7 days.

(Machining)

(After machining)

(Inspection by microscope)

4.Can SuNPe do any surface finish?

SuNPe have rich experience on CNC machining, but also an expert on surface finish, we can do sandblasting, transparent plastic polishing, metal polishing, grey primer, glossy painting, e-coating, transparent color painting, colorful anodizing, chrome plating, powder coating, brushing, Logo printing, PVD coating, laser engrave, transparent polishing, micro-arc oxidation, plating , dye, etc.

1.Overview of the plastic prototype project.

Manufacturing process: CNC machiningMaterial: PMMA

Surface finish: Deburred

Lead time: 7 days.

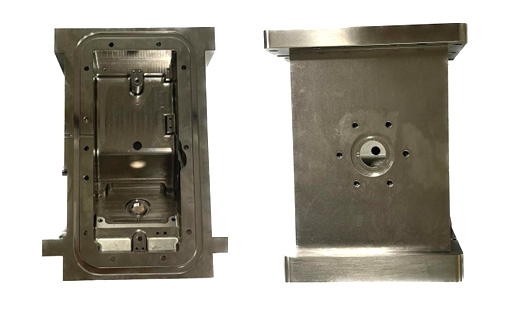

2.Make the parts

It is extraordinarily important to reduce the machined marks and make the machined marks slightly to achieve the good roughness and keep the transparency of the clear parts. Our engineering team confirmed the optimal processing plan after discussion. We used R1.5mm, 0.3mm, 0.5mm cutters, high speed and low feed to machine the small slots to ensure they can be machined accurately and keep the surface roughness of slots and other surfaces well.

(Machining)

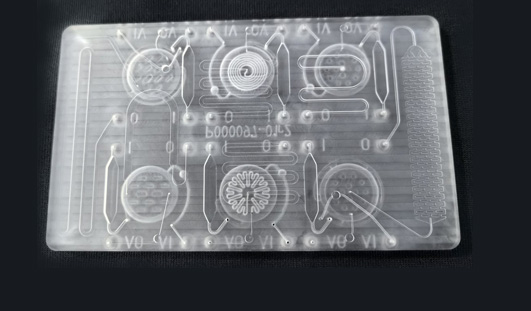

3.Surface Inspection.

After it passed the dimension inspection, we used handheld microscope to check the surface of the slots to ensure the machined mark is shallow and no dust on the slots.

(After machining)

(Inspection by microscope)

4.Can SuNPe do any surface finish?

SuNPe have rich experience on CNC machining, but also an expert on surface finish, we can do sandblasting, transparent plastic polishing, metal polishing, grey primer, glossy painting, e-coating, transparent color painting, colorful anodizing, chrome plating, powder coating, brushing, Logo printing, PVD coating, laser engrave, transparent polishing, micro-arc oxidation, plating , dye, etc.