What a Wonderful Scientific Project Machined by SuNPe

- designer:

- Types:

- Craft:

- time:2023-03-18 08:21:19

- Pageviews: time

- Service Content:SuNPe specialized in prototyping, CNC machining and manufacturing over 18 years, we’ve provided a lot of successful professional solutions to our customers in scientific instrument industry.

- Preview:View

SuNPe specialized in prototyping, CNC machining and manufacturing over 18 years, we’ve provided a lot of successful professional solutions to our customers in scientific instrument industry.

What a Wonderful Scientific Project Machined by SuNPe

Overview:

SuNPe specialized in prototyping, CNC machining and manufacturing over 18 years, we’ve provided a lot of successful professional solutions to our customers in scientific instrument industry....

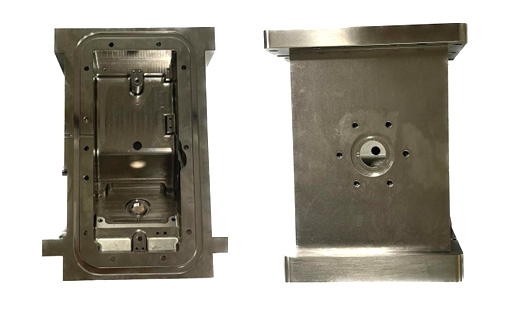

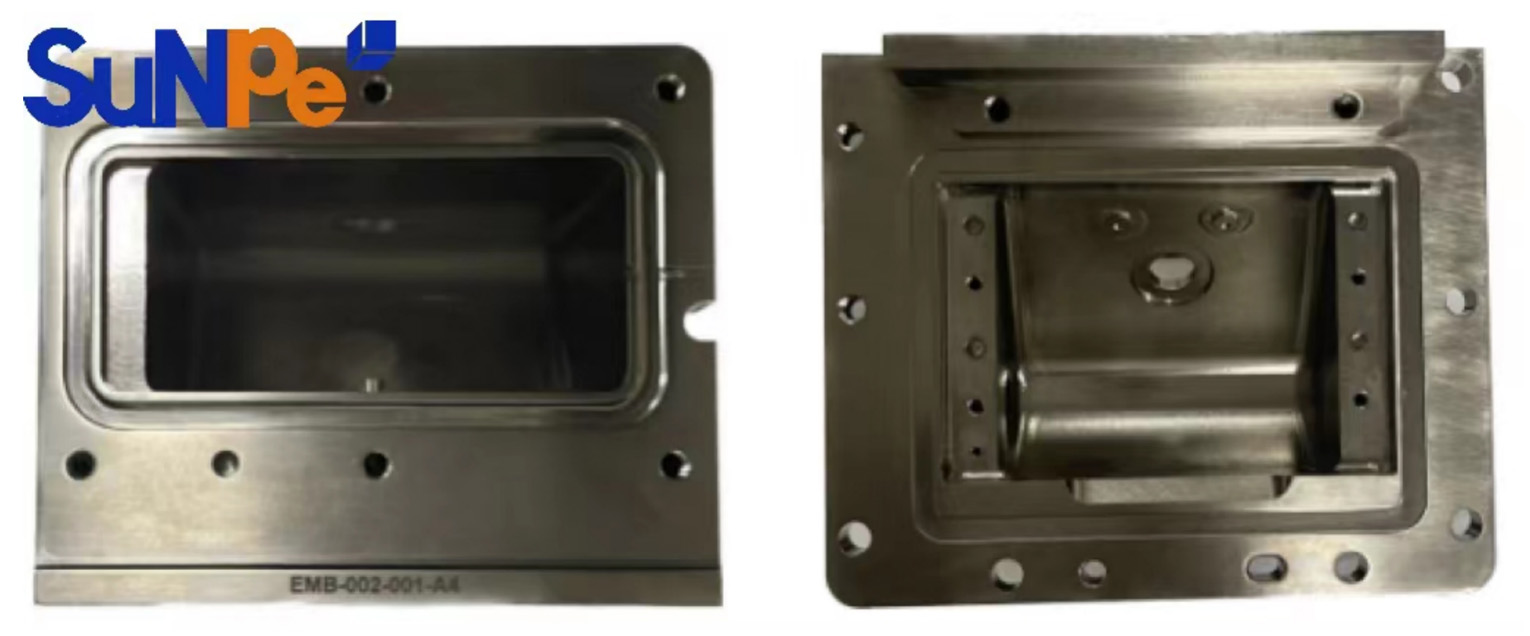

The customize demands for scientific instruments

With the development of automation and intelligence in the scientific instrument industry, more and more scientific instrument customer need a functional prototyping for their R&D and testing, including laboratory analytical instruments, life sciences, chromatography instruments etc. SuNPe specialized in prototyping, CNC machining and manufacturing over 18 years, we've provided a lot of successful professional solutions to our customers in scientific instrument industry.Here is a successful case, this scientific instruments combines 3 and 4 axis CNC machining, EDM, and laser marking to achieve the demand of air tight, ensure the multi-face assembly and recognized.

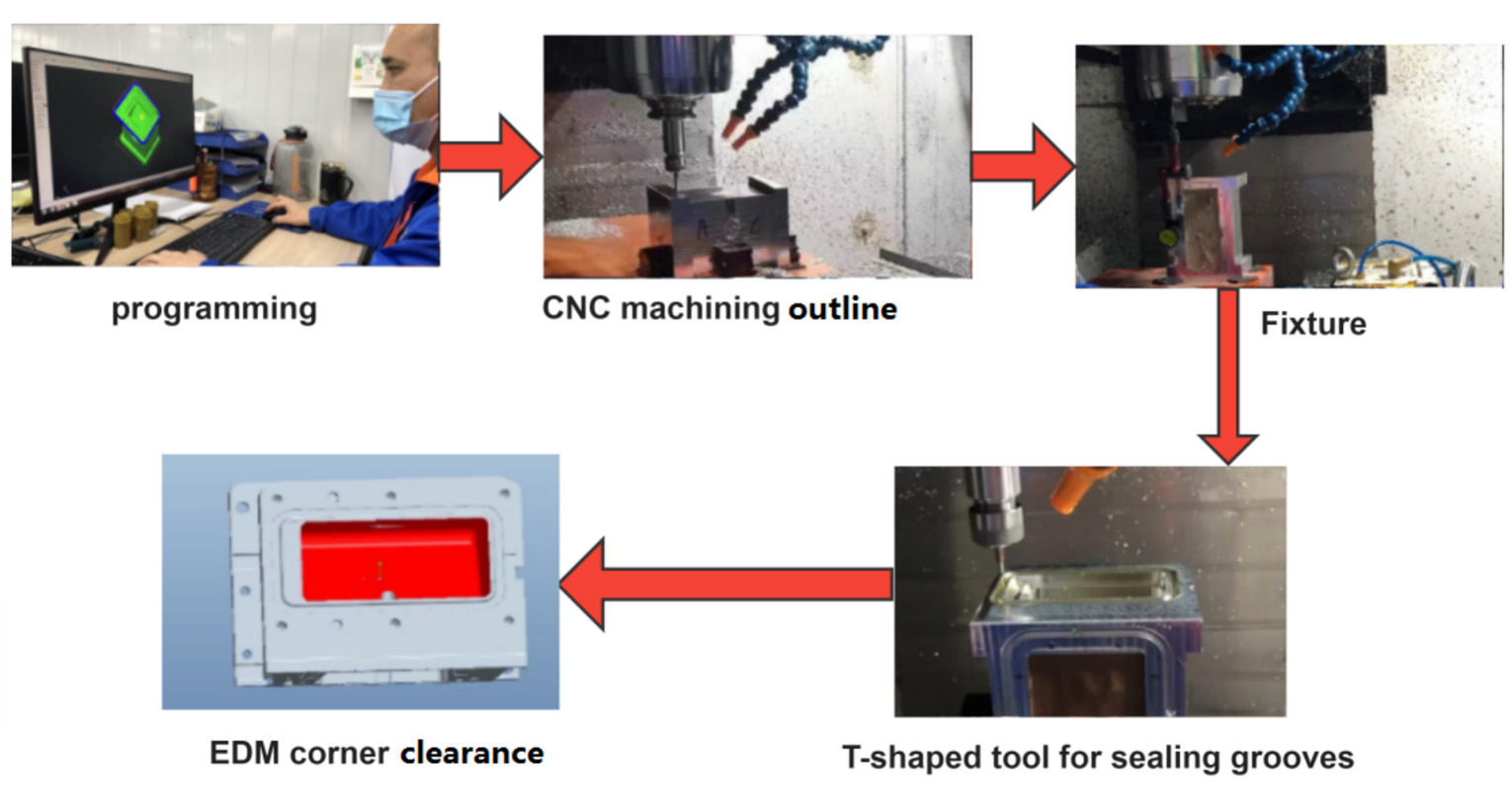

1.Multiple technic combined when machining.

To meet the requirement of Ra0.8um surface roughness and 8 sealing grooves, we combined 3 and 4 axis CNC machining, EDM technology to process such a challenging part.1) Turn-over 6 directions to process outline by 3-axis CNC machines, in this step, we need to achieve Ra1.6um roughness directly by CNC machining.

2) Building fixture, use 4-axis machining 2 internal faces, T-Shape tool to produce O-Ring grooves and achieve Ra0.8um roughness.

3) EDM the corner to meet R2 radius as per CAD data.

(CNC machining, Fixture, EDM clearance)

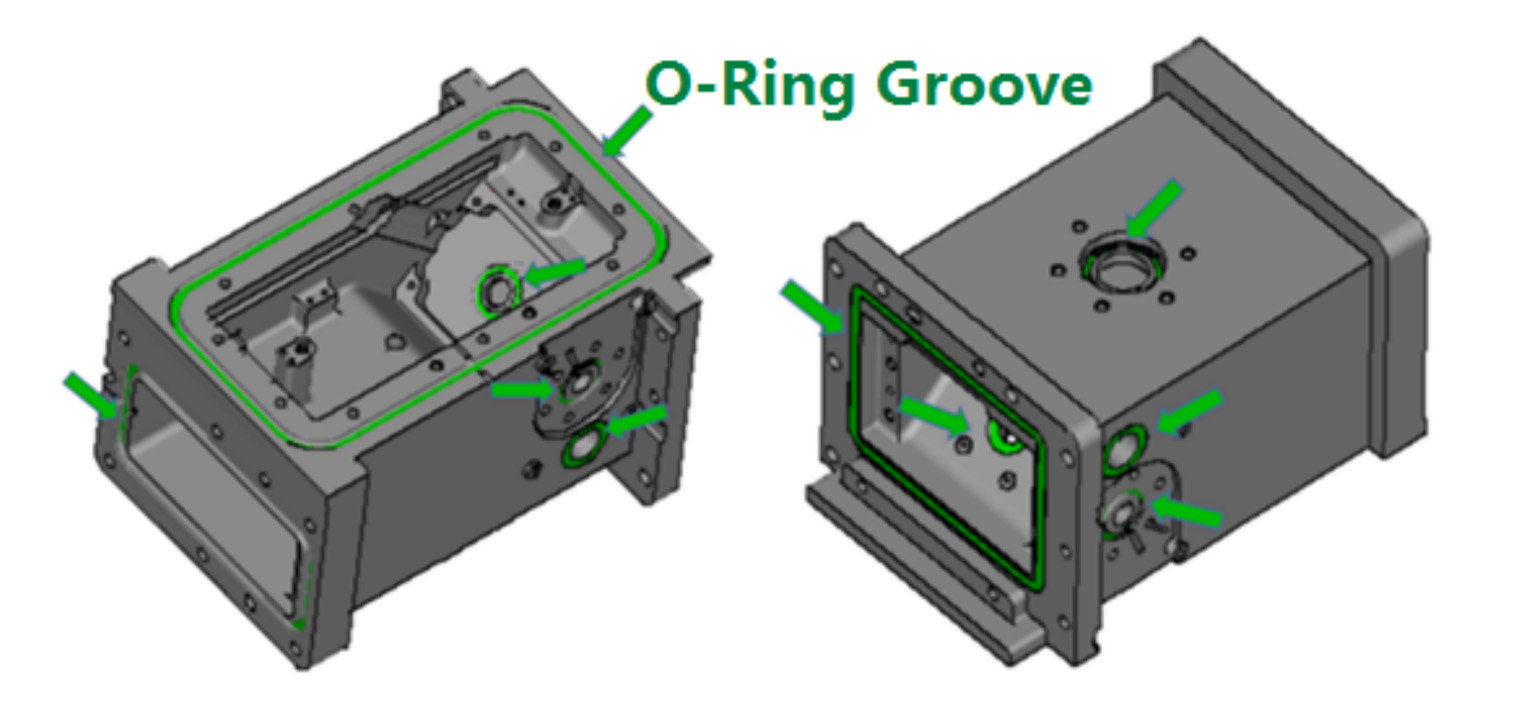

2.Realize 8 O-rings sealing performance,

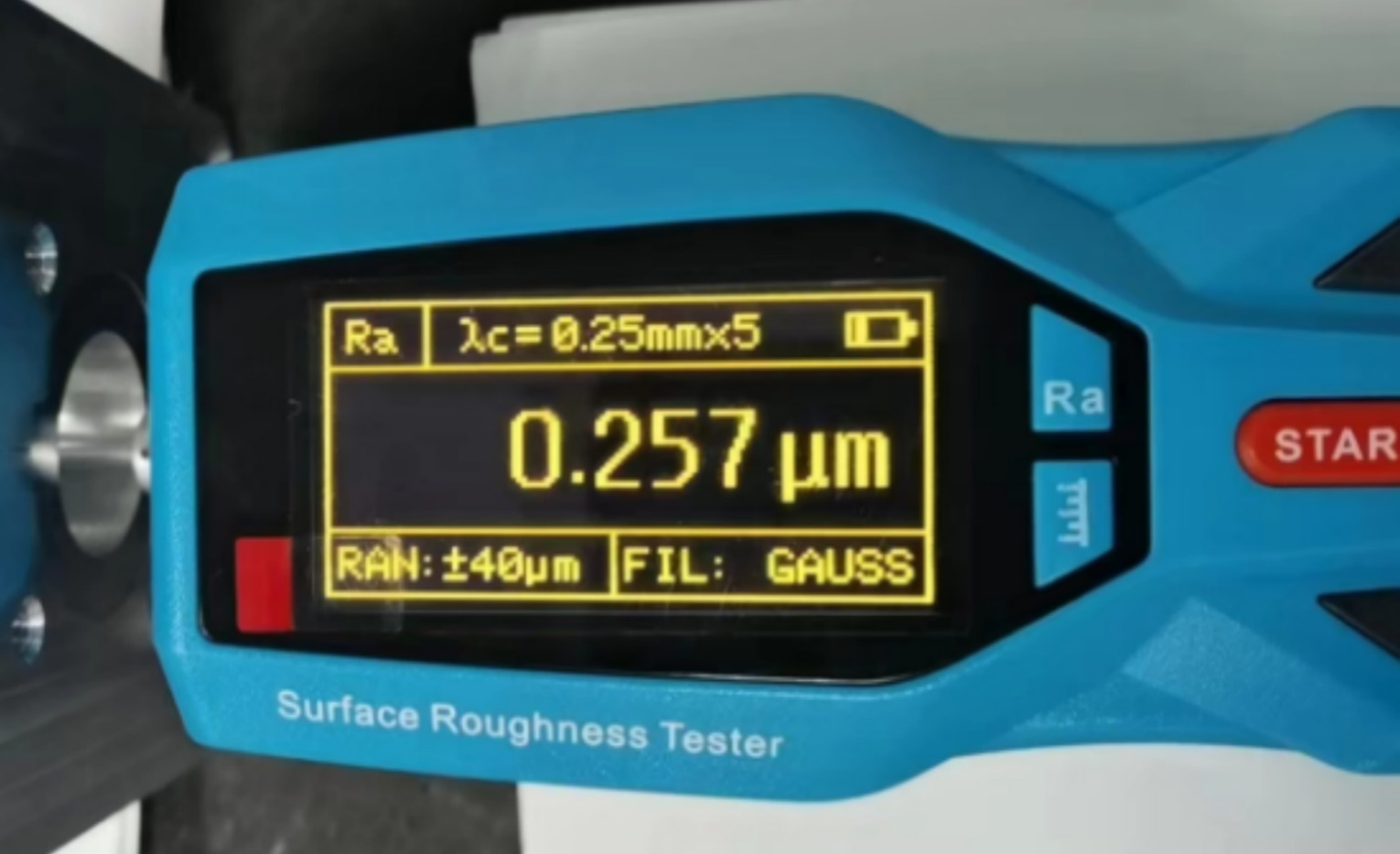

Following below picture, there're 8 O-Ring grooves in 5 different directions, the roughness of the grooves have to achieve sealing effect to ensure the durability and the mating surface air tight when use. So CNC machining O-Ring grooves in Ra0.8um without tool marks, and control the flatness in tolerance is the most important to achieve the sealing performance perfectly.

(O-Ring Groove)

( Roughness Testing )

3.Series Surface finish applied for scientific instrument prototype.

According to the purpose of the part, we recommend electroless nickel plating on surface, to meet the requirement for conductivity, wear resistance and corrosion resistance. Meanwhile, to ensure the accuracy of assembly positions, such as holes, dowel pins, as well as the threads, we have carried out special protection for them to ensure that they are free of nickel plated layer.Besides, laser marking is applied when finished nickel plated, for better identification during using.

(Nickel Plated, laser marking)

Obtaining more customize information for your scientific instrument prototyping, CNC machining parts or low volume production, please contact us.