CNC Machining Service

With hundreds of CNC machines, our unmatched in-house capacity ensures your parts are shipped on-time, every single time. At SuNPe, our ISO 9001:2015-certified CNC machining facilities are designed for both rapid prototyping and low-volume production of end-use components.

CNC Machining FAQs

1.How to do CNC business with SuNPe

Please send 3D CAD data in one of the following formats (CATIA, IGS, STP, X-T), you can also send 2D drawing in PDF or AI to show us more details about tolerance and hole's requests.

Including your requirement about material, quantity and surface finish will be much appreciated.

We will give you a quotation within 24 hours.

2.What is the difference between CNC milling and CNC turning?

Turning rotates the part against the tool. It mainly uses round bars to process parts. Milling rotates the tool against a stationary part. It mainly uses square or rectangular bars to produce components.

3.What tolerance can CNC machining achieve normally?

The tolerance of CNC milling can reach 0.025mm-0.05mm, and the tolerance of CNC turning can reach 0.02mm. These tolerances depend on the size and characteristics of the part to be evaluated. Please contact us for a more accurate assessment.

4.How to machine the internal sharp corners that cannot be machined by CNC?

We have Electrical discharge machining (EDM) service , EDM can be used to clear corners.EDM is a specialized form of CNC machining. Controlled pulses of electricity are used to erode even the hardest metals with great precision. This is essential when machining hardened tool steels. When done correctly, the surface finish is mirror-smooth and requires no secondary polishing.

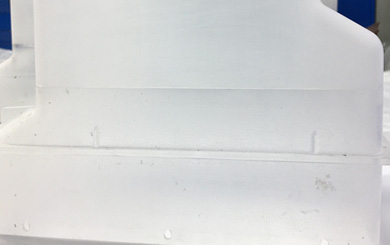

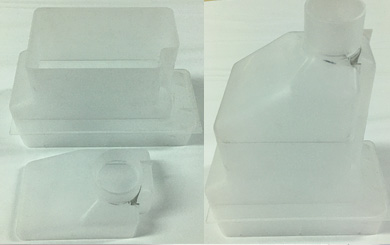

5.What is the difference between machined as one piece and split & glue?

Since part features cannot be processed as one piece, we can choose the split and glue scheme.

The price of split & glue will have advantages over as one piece. If you're in the prototype stage, or if the part doesn't have to endure a lot of strength, split & glue is a better option.