Medical Part Manufacturing

From Prototyping

To Low-volume Production

SuNPe Can Help You with Medical Parts

SuNPe has been specializing in prototyping and production, and we are able to help various medical parts from concept to market. So far we have achieved all kinds of medical components for health care product, rehabilitation device, surgical apparatus and so on, and we would like to keep developing our capacity for medical industry in the future.

What kinds of medical parts can be achieved by SuNPe ?

No matter you require plain parts or complex components of medical equipment, SuNPe can certainly help, as we have been processing various medical projects and we have got experience and skills from the job we keep going on. Please just review the categories below that may be helpful for you:

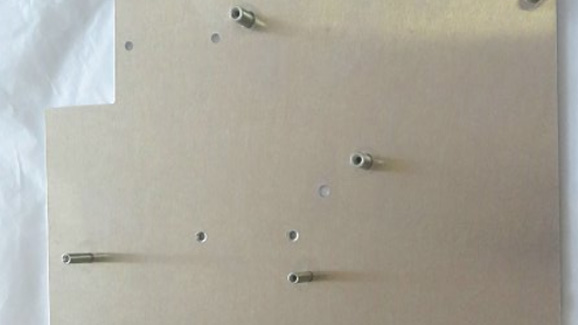

Medical Accessories

SuNPe typically applies CNC machining (milling, turning, lathe) for medical small pieces to achieve perfect precision and features, so that the parts can work well for assembly, we can provide a wide range of materials like stainless, brass, tungsten steel and other available materials that can meet customer’s desirable specification.