Vacuum Casting Service

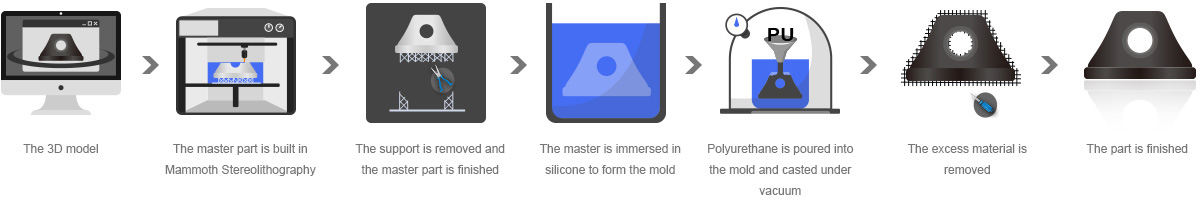

Vacuum Casting is a widely used process in rapid prototyping, typically used for building 10 to 50 pieces of functional prototypes out of broad range of polyurethanes and other polymers. We can accurately reproduce the prototypes with original color, over-mold, texture and geometries from the master model and components.

Vacuum Casting Service

Direct suction casting

Put the shell made by ordinary investment molding process in the sealed chamber, the sealed chamber is lowered, and the sprue is inserted into the liquid metal.

How Does Vacuum Casting Work?

We make great tools for low-volume manufacturing,especially when quantity for hundreds and thousands of parts, we can use aluminum and Steel material to build the mold. To shorten lead-time and reduce cost, we share the mold base and different mold cavity. The material used will depend on the type of resin, characteristics of the parts and the number of parts you required.

SuNPe Vacuum Casting

Take you into our Vacuum Casting factory

SuNPe Vacuum Casting

Welcome to visit the production workshop of sunpe Vacuum Casting online, which will show you the entire production process of Vacuum Casting.

Vacuum Casting Advantages

Here are several advantages with Vacuum Casting. High productivity, various PU materials for selection, colorful tinted vacuum casting, multiple texture for options, over-molding and cost effective.

Vacuum Casting Workshops

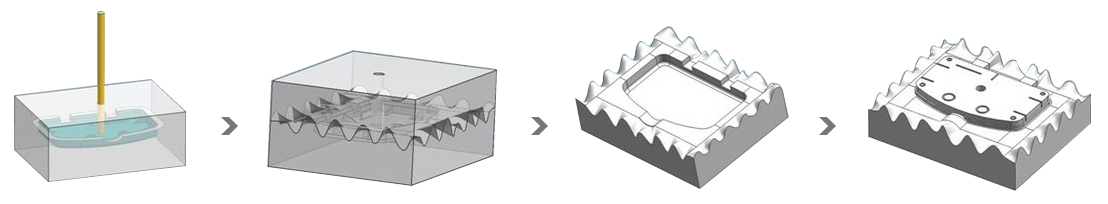

There are 4 vacuum casting workshops at SuNPe.The maximum size that our machine can make is 2200mm*1200mm*1000mm. At present, the maximum weight we can do is 7 kilograms. There are 3 steps to do vaccum casting, let's check.

The Capability For The Vacuum Casting

SuNPe owns 10 sets of vacuum casting machines, which can cast prototypes with the max dimension up to 2200mm*1200mm *1000mm.

We can accurately reproduce the prototypes with original color, over-mold, texture and geometries from the master model and components. These plastic castings will closely represent the mechanical properties of the intended production parts from a steel mold. One silicone mold can cast about 15 to 20 pieces of parts, depends on complexity, painting or original color, size and other factors in different parts. The typical lead time is 7 working days for 10 parts.

.