Tooling and injection molding at SuNPe

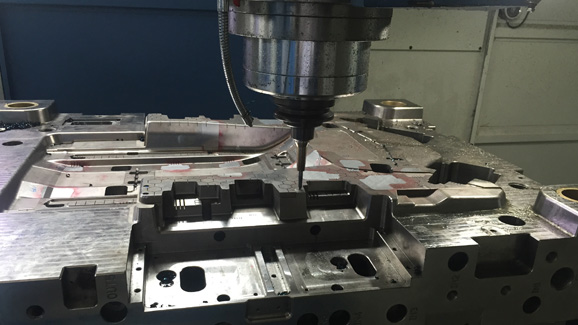

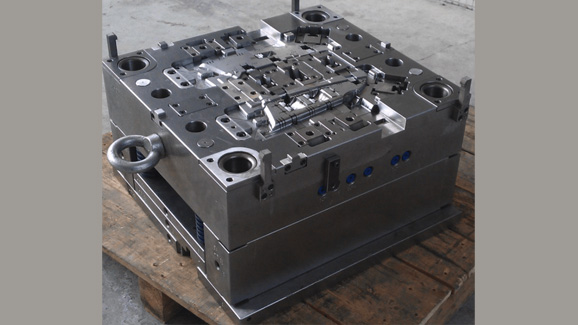

What is tooling?

It's well known that tooling is the method of obtaining the manufacturing components and machines needed for production. There are many kinds of machine tooling, such as fixtures, molds, dies, cutting equipment, extrusion tooling. Proper tooling for our customer prototyping or low volume series production projects directly affects product delivery time, quality and cost.

No matter metal and plastic rapid prototypes, low-volume series production projects, or mass production projects, SuNPe can offer rapid tooling or production tooling service to realize our customer products as a low cost and short time.

What is rapid tooling?

It is well known that rapid tooling is a kind of mold manufacturing method that can shortens time and reduces production cost. It is suitable for rapid prototypes and low-volume production project.

How SuNPe can benefit your rapid prototype projects or low-volume production projects by use rapid tooling service?

● Use soft tool by aluminum, P20, S136H or NAK80 steel.

● Build the family mould to reduce tooling cost.

● Share the mould base.

● Simplify the complex tooling structure by post-machining.

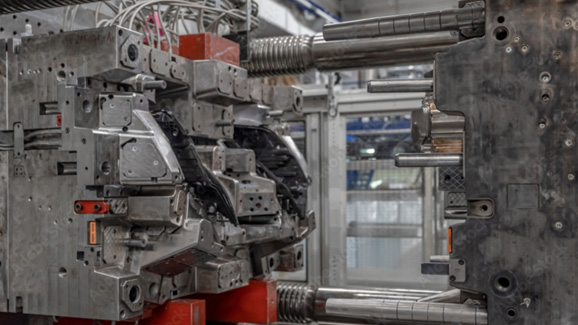

Production Tooling

Different with rapid tooling, production tooling is the most economical manufacturing way, which can bring your product to the market with stable high quality. At SuNPe, we will use hard steel for production tools to achieve huge service life.

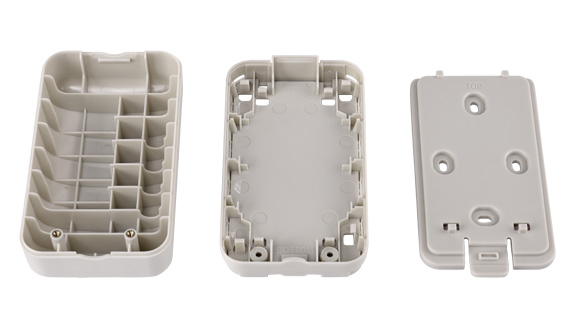

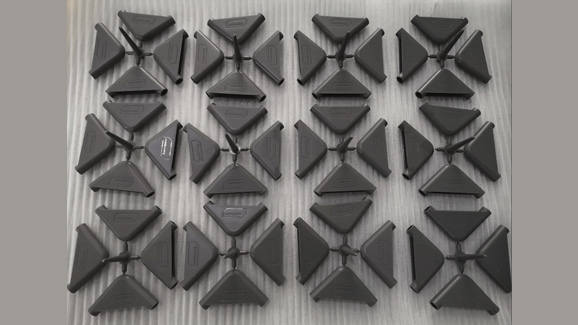

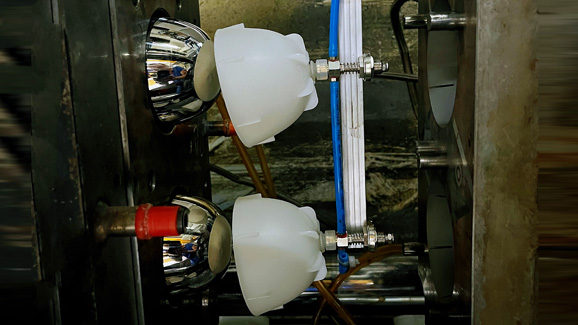

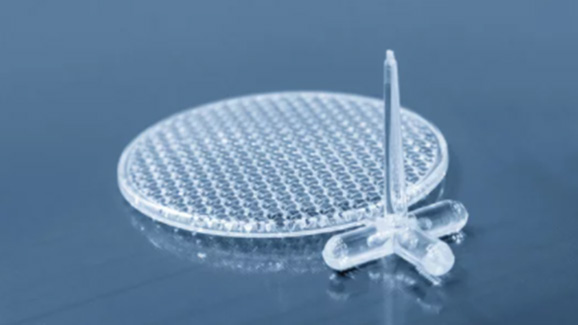

Plastic Injection Molding

What does plastic injection molding mean?

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them.

At SuNPe, our plastic injection molding service can satisfy our customerinjection molding prototypes, mass injection molding production projects with short time and high quality.

Why use injection molding prototypes service?

In the preliminary design stage, rapid prototyping technology is needed, such as CNC machining, vacuum casting, 3D printing, etc. Before bring the products to the market, it is necessary to evaluate the product function by used "real materials". And the injection molding prototypes is the most cost-effective way.

At SuNPe, we have rich experience with injection prototypes by use "real materials", such as PLA LX175, Makrolon 2407 etc, for medic and consumer and customer electronics products.