3 Sets Assembly For Wool Testing Equipment Shell

- designer:

- Types:

- Craft:

- time:2020-10-30 17:29:55

- Pageviews: time

- Service Content:CNC machining, Laser cut&Sheet metal&Riveting, Vacuum casting, Lathe.Also supply fasteners, assemble, packaging and delivery.

- Preview:View

This client is a wool testing company, they have many testing equipment that need mteal shell and install electrical components inside.

3 Sets Assembly For Wool Testing Equipment Shell

Overview:

This client is a wool testing company, they have many testing equipment that need mteal shell and install electrical components inside....

3 sets Assembly for Wool Testing Equipment Shell

This client is a wool testing company, they have many testing equipment that need mteal shell and install electrical components inside. This project is for 3 sets shell assembly, need functional and excellent appearance.

1. Services for this project: CNC machining, Laser cut&Sheet metal&Riveting, Vacuum casting, Lathe.Also supply fasteners, assemble, packaging and delivery.

Different surface finish including painting(solid color and clear lacquer), powder coat, laser etch, etc.

2. Prototypes lead time: 14 days to finish 3 sets(total 9 assemblies)

Assemble and packaging lead time: 2 days

3. Material: AL 5052, AL 6061, SS 304, Black ABS, Black PMMA, PU 8400.

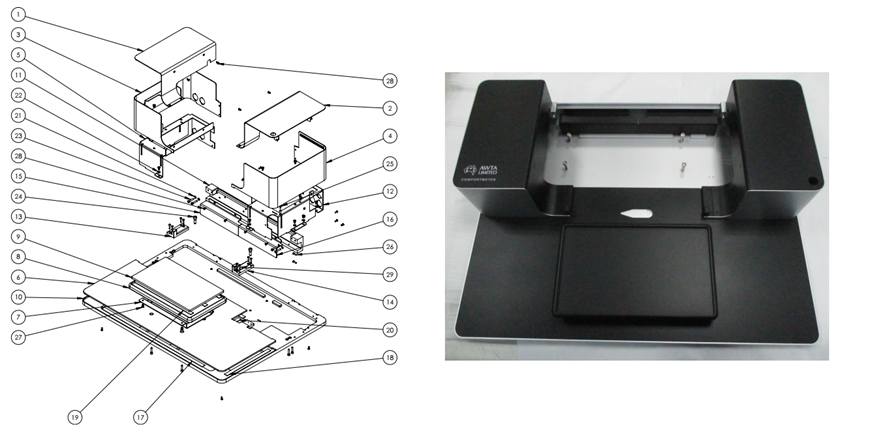

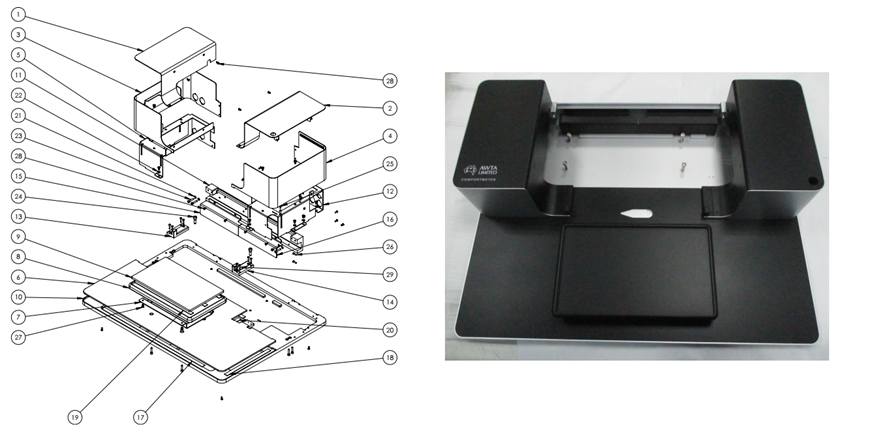

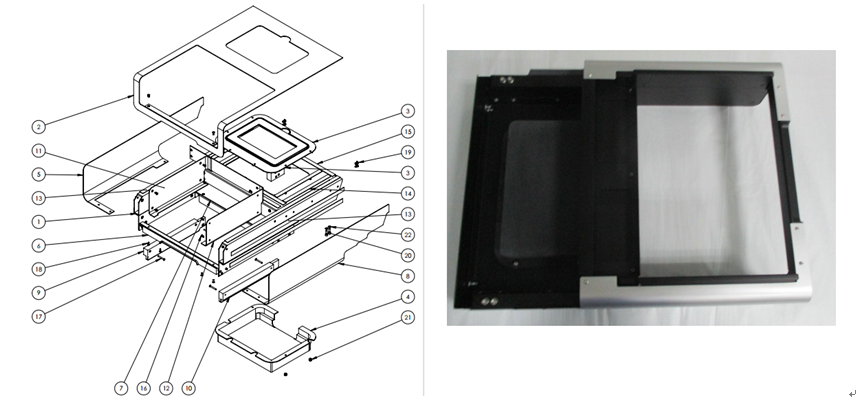

The first assembly: Clamp Assembly

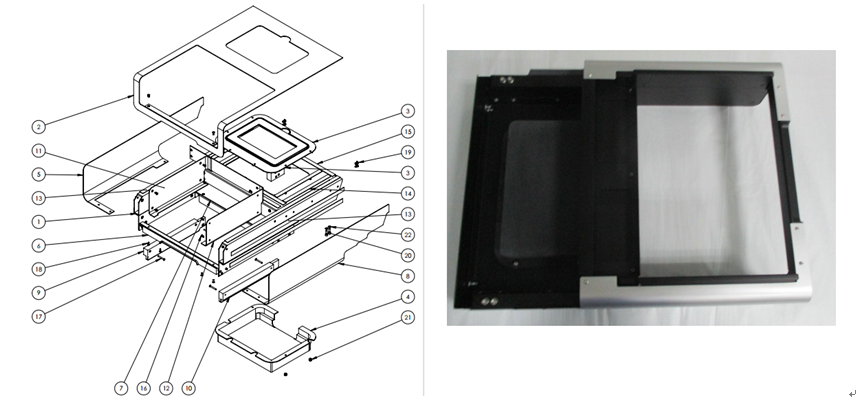

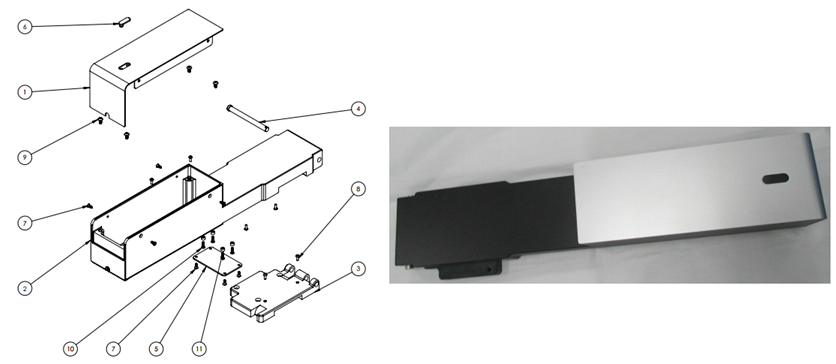

The second assembly: Base Assembly

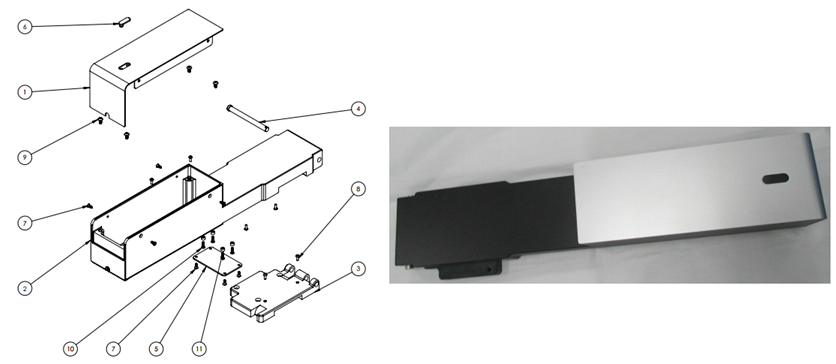

The third assembly: Head Assembly

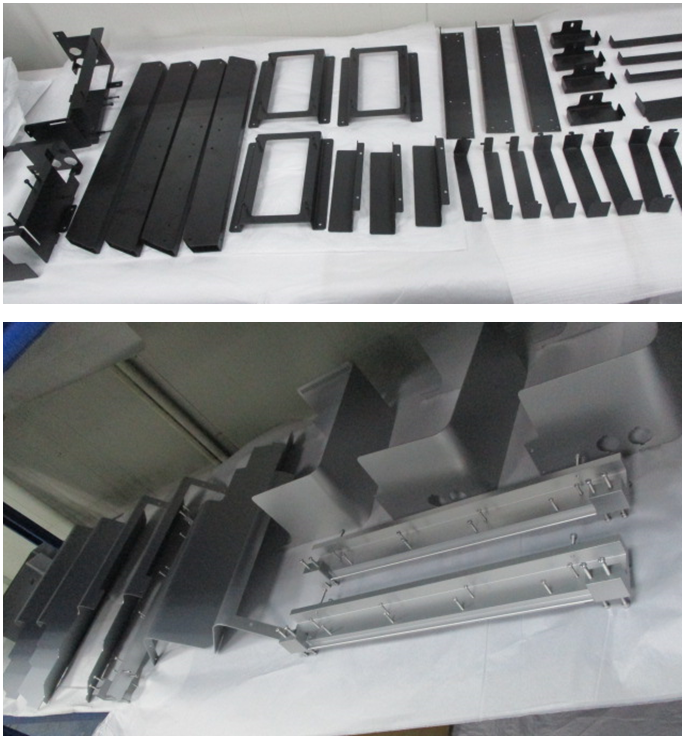

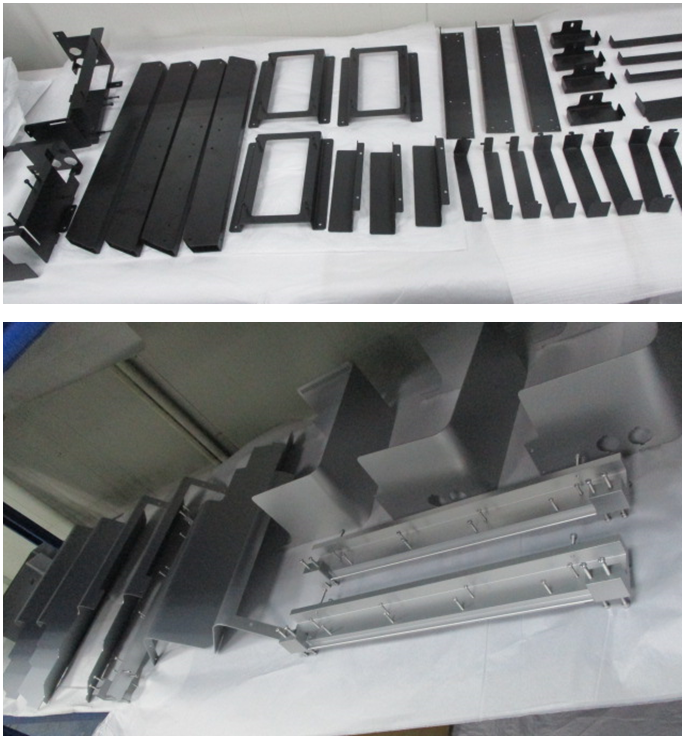

Sheet metal and laser cut process:

For this project, most of these parts manufactured by laser cutting, sheet metal, bent then add rivets and nuts.

Also including some L shape Al 6061 material , standard Al 6061 Tube cutting.

Finishedparts after sheet metal and bent.

Other Process

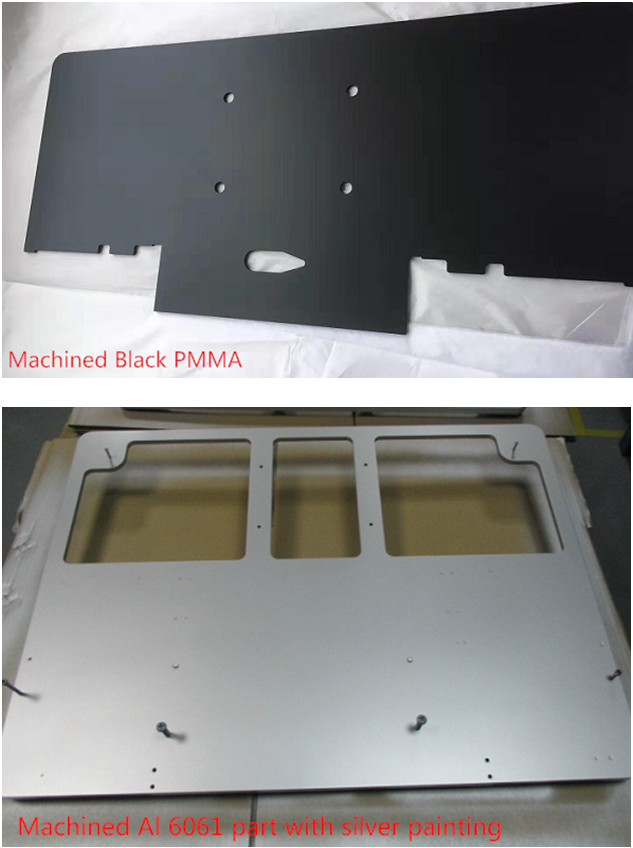

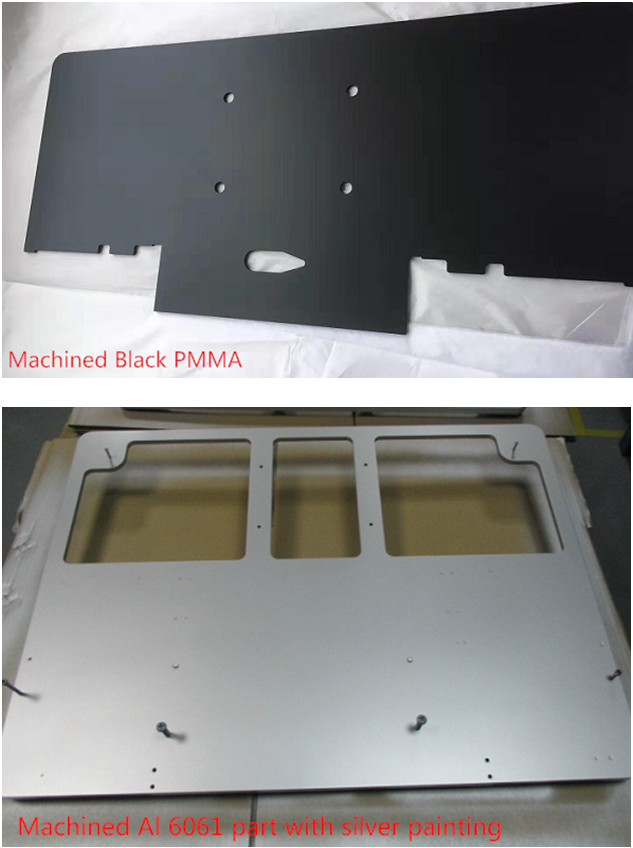

Some metal and plastic parts manufactured by CNC.

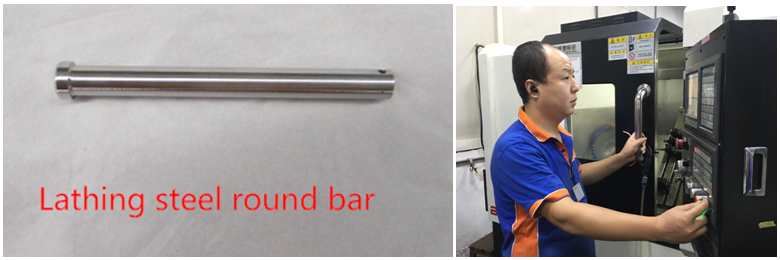

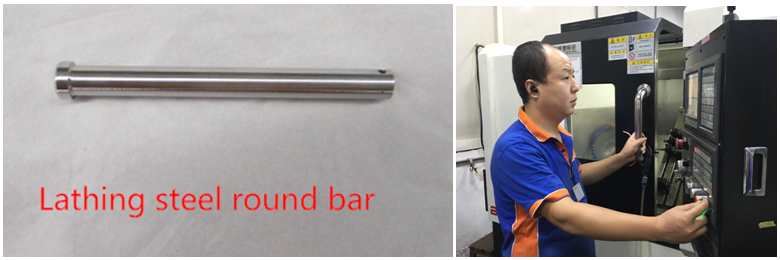

Metal parts manufactured by CNC lathe.

Plastic parts(elastomer) manufactured by vacuum casting.

Surface finish

Assembly

We assembled and use adhesive bond and rivets as well as screwsas client's specification to assemble some parts together.

Packaging and delivery

Before packaging, we check overall assembly.

Packaging and delivery

Handmade cartons and iron shelf to make sure safe packaging and delivery.

This client is a wool testing company, they have many testing equipment that need mteal shell and install electrical components inside. This project is for 3 sets shell assembly, need functional and excellent appearance.

1. Services for this project: CNC machining, Laser cut&Sheet metal&Riveting, Vacuum casting, Lathe.Also supply fasteners, assemble, packaging and delivery.

Different surface finish including painting(solid color and clear lacquer), powder coat, laser etch, etc.

2. Prototypes lead time: 14 days to finish 3 sets(total 9 assemblies)

Assemble and packaging lead time: 2 days

3. Material: AL 5052, AL 6061, SS 304, Black ABS, Black PMMA, PU 8400.

The first assembly: Clamp Assembly

The second assembly: Base Assembly

The third assembly: Head Assembly

Sheet metal and laser cut process:

For this project, most of these parts manufactured by laser cutting, sheet metal, bent then add rivets and nuts.

Also including some L shape Al 6061 material , standard Al 6061 Tube cutting.

Finishedparts after sheet metal and bent.

Other Process

Some metal and plastic parts manufactured by CNC.

Metal parts manufactured by CNC lathe.

Plastic parts(elastomer) manufactured by vacuum casting.

Surface finish

Assembly

We assembled and use adhesive bond and rivets as well as screwsas client's specification to assemble some parts together.

Packaging and delivery

Before packaging, we check overall assembly.

Packaging and delivery

Handmade cartons and iron shelf to make sure safe packaging and delivery.

I like this design

Contact us now

- Previous: One Stop Service for Boca Boot Project

- next: The Kinetic Reflex