CNC Machined Low-volume Aluminum Crane Project

- designer:

- Types:

- Craft:

- time:2023-04-15 08:22:27

- Pageviews: time

- Service Content:With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. SuNPe helped this Aluminum crane project from prototype to low-volume production for 4-axis CNC machining with hard anodized finish. Moreover, we done CMM inspection to confirm every dimension under control.

- Preview:View

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. SuNPe helped this Aluminum crane project from prototype to low-volume production for 4-axis CNC machining with hard anodized finish. Mor

CNC Machined Low-volume Aluminum Crane Project

Overview:

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. SuNPe helped this Aluminum crane project from prototype to low-volume production for 4-axis CNC machining with hard anodized finish. Mor...

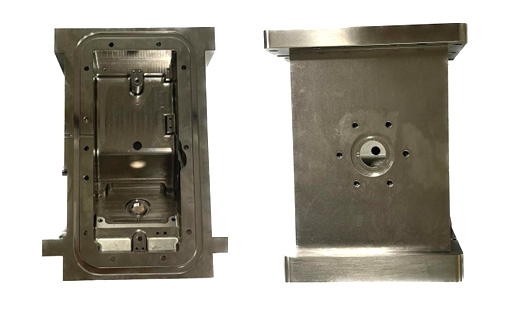

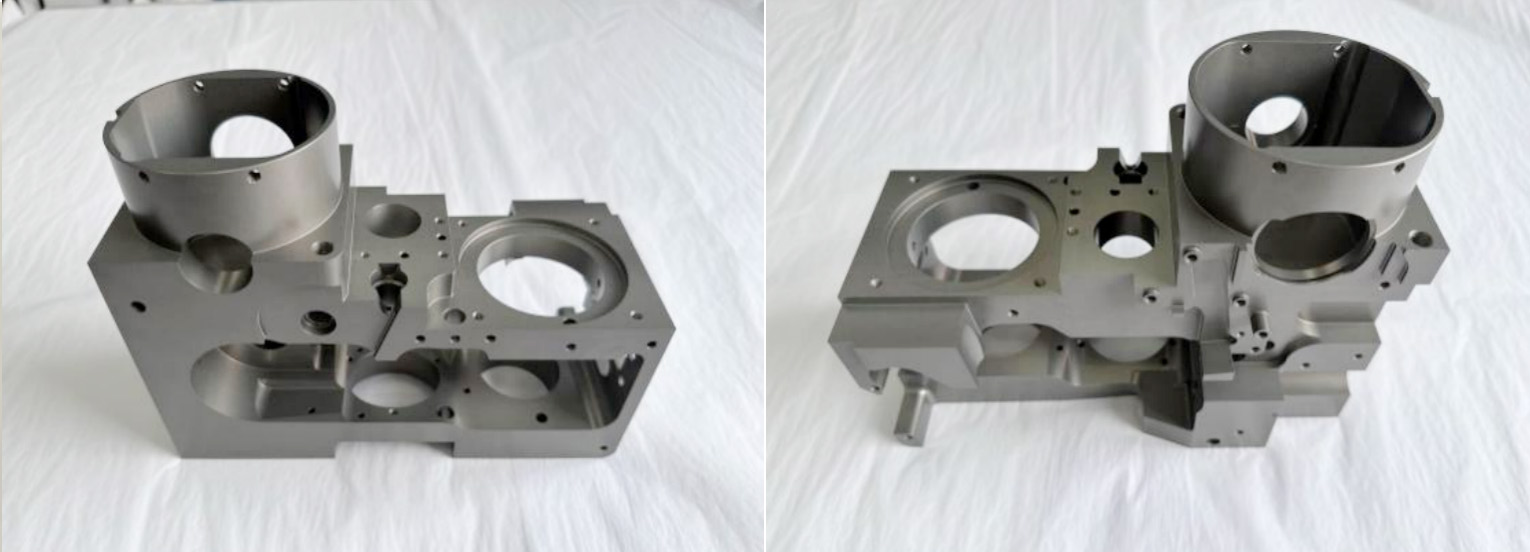

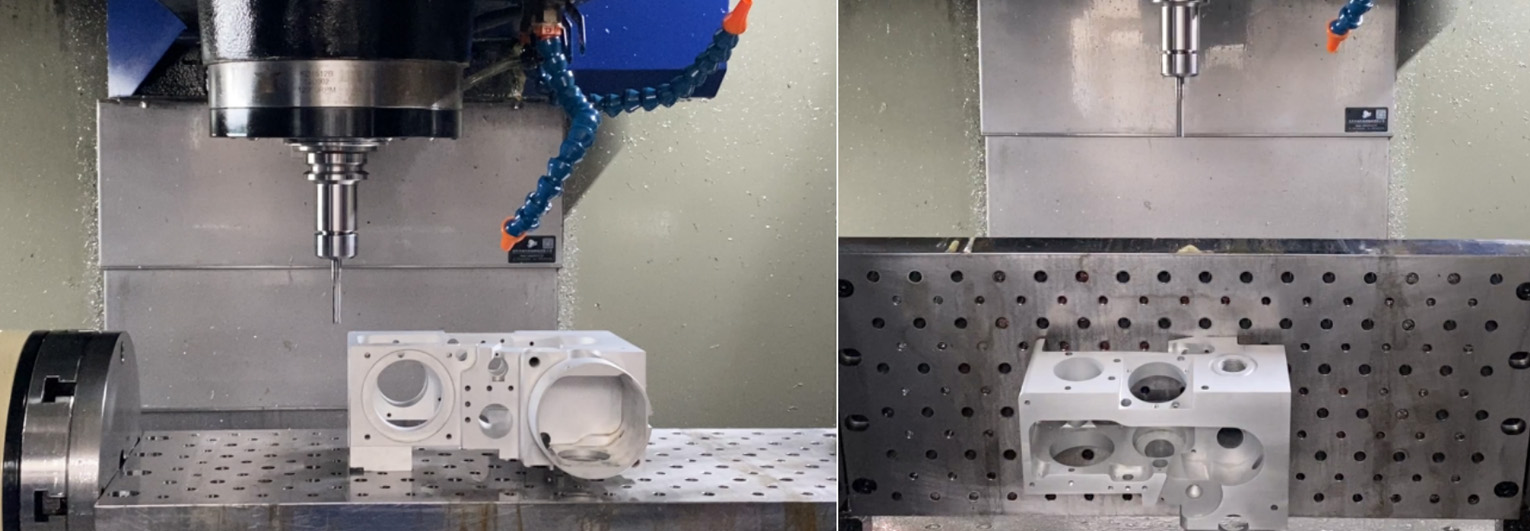

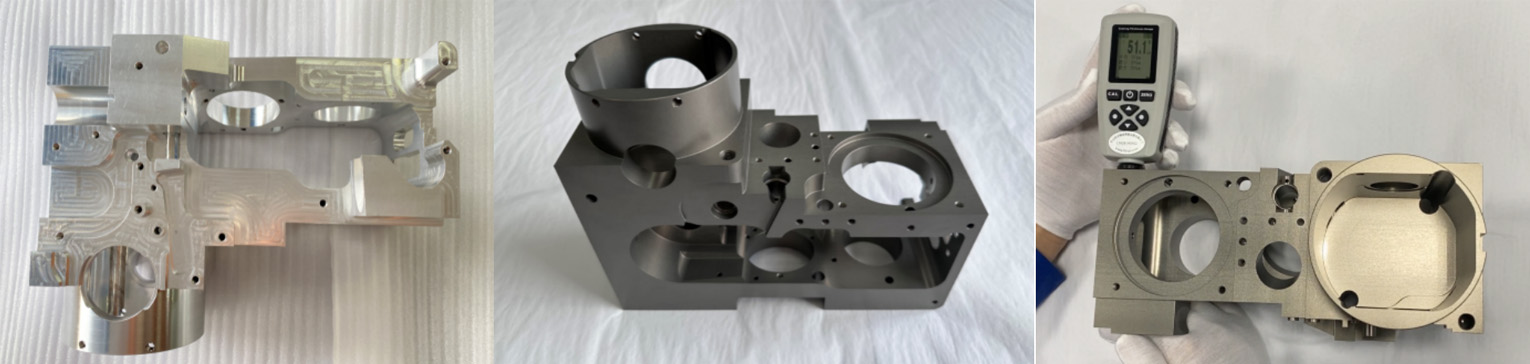

We do an project of aluminum crane part for our customer. For this project, we use AL6061-T6 material for CNC machining. It can make the machining plane of the cutting tool more extensive, reduce the repeated clamping of the part, improve the overall machining accuracy of the part, simplify the process, and improve production efficiency.

(4-axis CNC machining the part)

We evaluated this project feasibility from the quotation stage, and provided the Pre-DFM to the client in order to save the developing time and production cost.

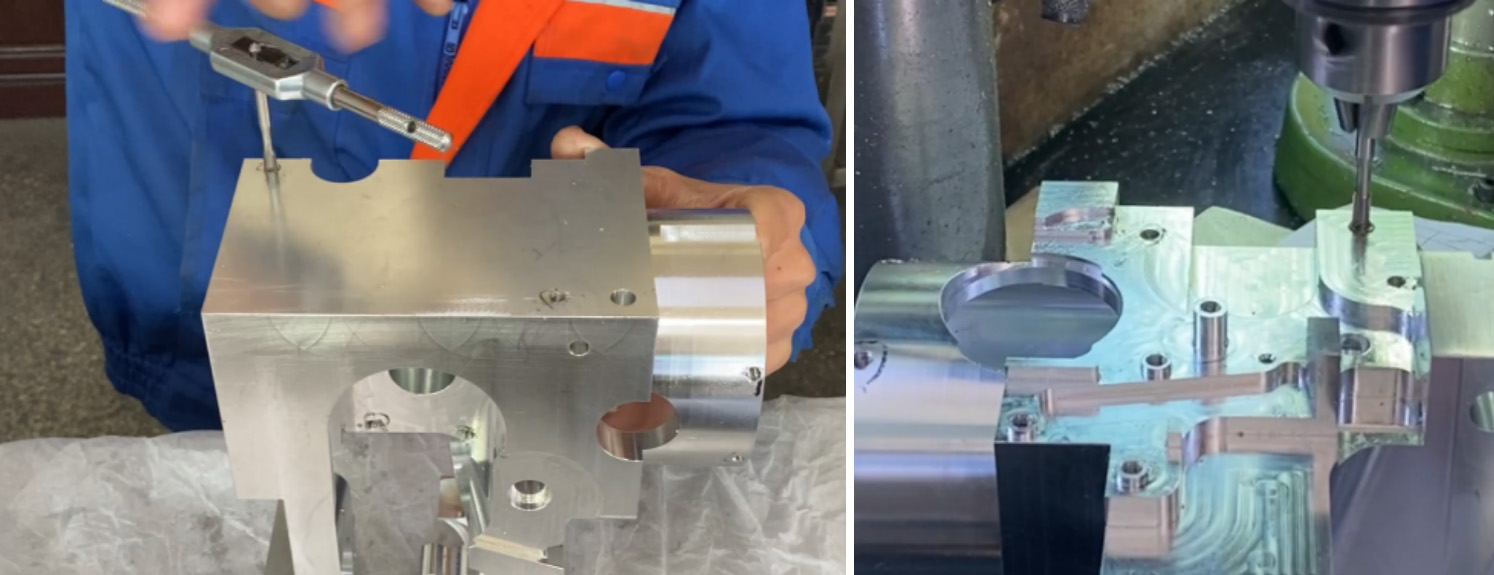

Once our customer confirmed the order, we organized the project meeting to make sure every department could know how to realize this design for customer.

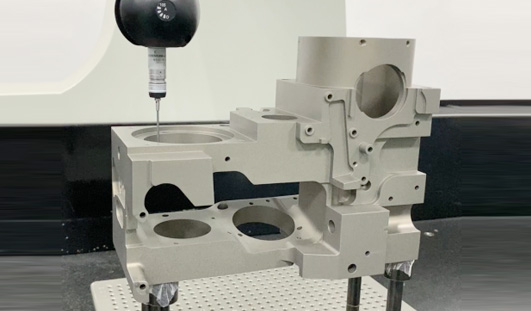

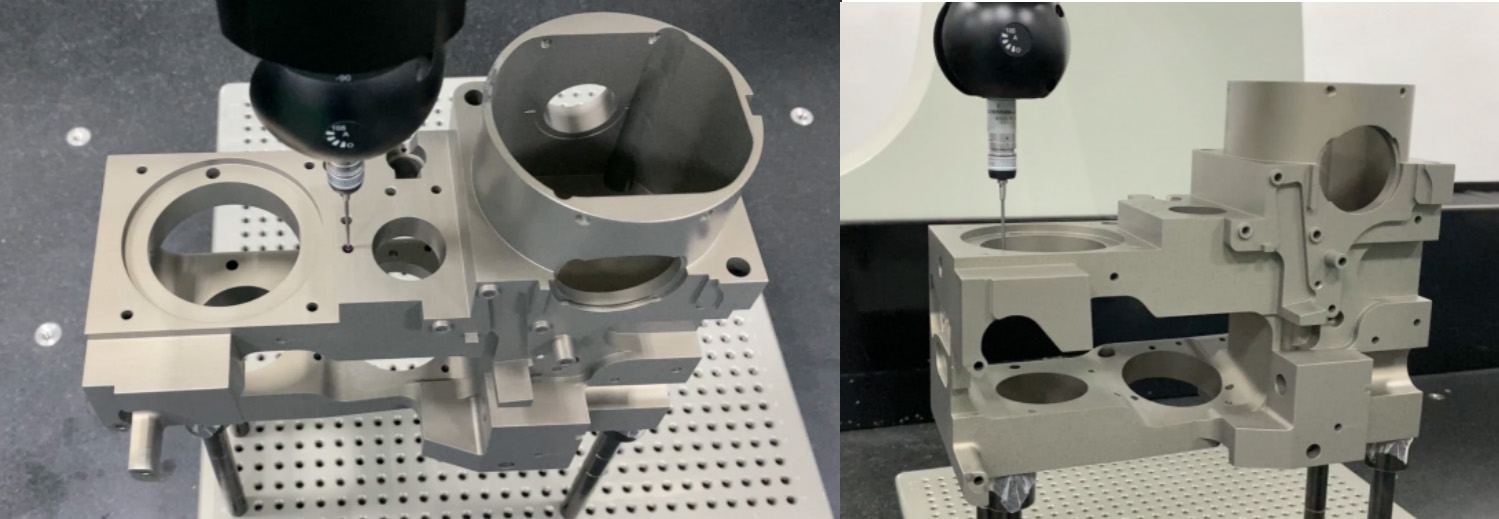

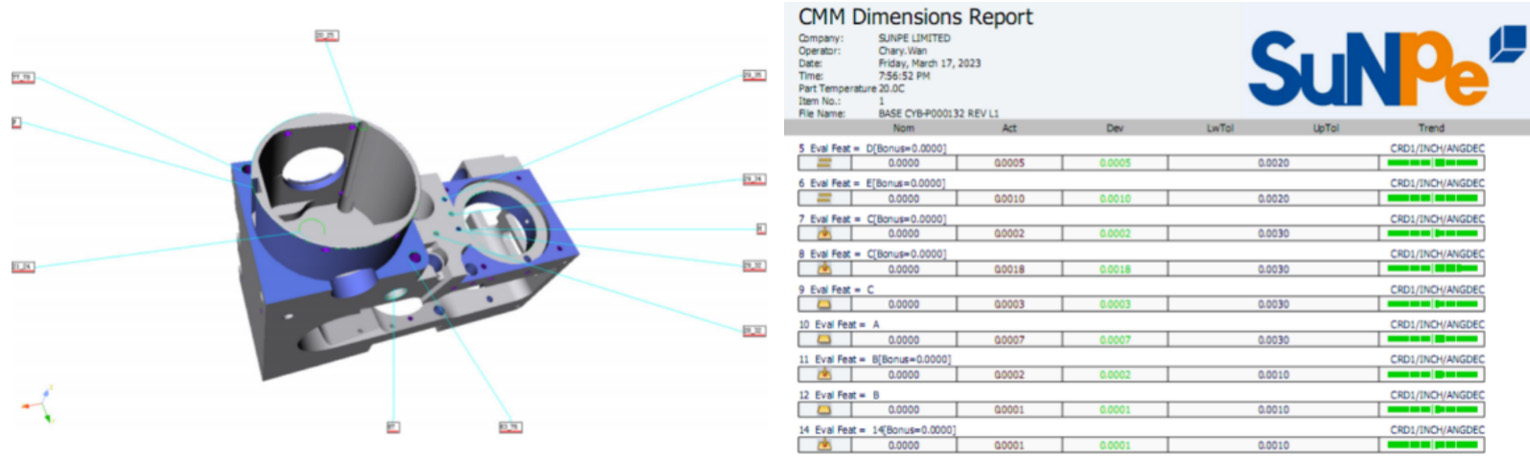

This part has more than 200 key dimensions, how to make sure the tolerance under control is critical. This project meeting could help us to make a good processing and control plan from the IQC to the IPQC, and to the FQC.

Only the FAI report was approved by our QC team and customer, then we can go ahead the rest of the pieces. We succeed to make the part within the tolerance before the surface finishing.

(Inspection by CMM)

(Tap thread)

(CMM inspection report)

Considering durability and practicality, we do hard anodize for the part which will be thicker and wear-resistant. At SuNPe, we will also consider the thickness and can reach the tolerance range to ensure post assembly if required. We will make sure the anodized thickness can meet requirement through testing.

(Hard anodized Before & After) (Anodized thickness testing)

Why SuNPe for Low Volume Aluminum CNC Machining?

1. Competitive techniques and surface treatment2. Advanced facilities and measuring instrumentation.

3. SuNPe can provide a variety of surface finishing services and one stop services for you.

4. Experienced inspectors for quality inspection

5. Well-trained sales representatives who can well understand what customer needs

6. SuNPe has passed ISO9001 certification and IATF16949 system certification, we have a comprehensive quality management system to ensure timely and high-quality completion of projects.

If you are looking for a reliable partner from prototype to low-volume production project, we believe SuNPe it’s your best choice. We are honored to help our customer to produce any products they need. Contact us to start your projects now.