Low-Volume Production at SuNPe

What is Low-Volume Production?

Low-Volume Production is a kind of service for the bridge between prototyping and series mass production, which is especially for the quantity from 50 to 100000. At SuNPe, Low Volume Production Service covering CNC Machining, Sheet Metal Fabrication, Urethane Casting, Plastic Injection Molding and Pressure Die Casting can help your any kinds of low-volume projects.

Not Only Prototyping

At SuNPe, we can also provide low-run production service based on your requirements, with our one-stop services from prototyping to low-volume production, we are able to achieve your desired parts by turning original design into market products.

Low Volume CNC Machining

CNC Machining at SuNPe is a good choice for low-volume production. First, we have more than 200 sets CNC machines and experienced staff running the working time of 24/7, so we have huge capacity and high efficiency to support CNC projects. Second, our CNC services include milling, turning, EDM, lathe and surface finishing, and they all can handle complex low volume parts. Third, various metal and plastic materials are available. Above all, we are able to use CNC machining to achieve precision parts in good quality and help the industries like automotive, home appliance, medical device, scientific products and so on.

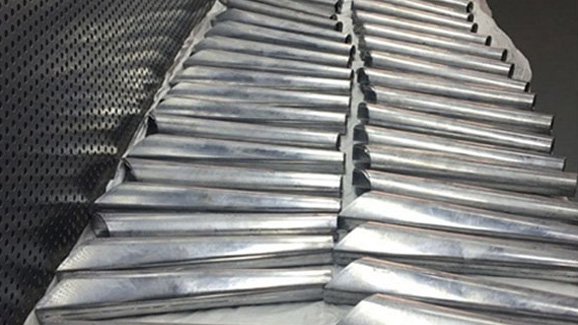

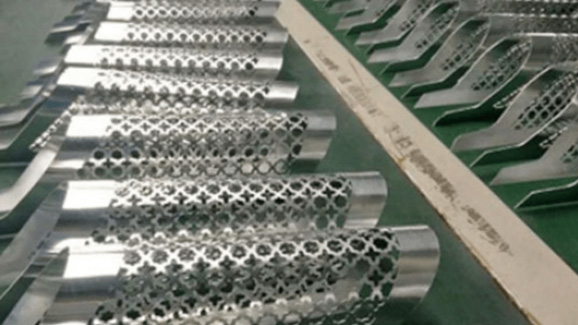

Low Volume Sheet Metal Fabrication

When you would like low-volume metal sheets, Sheet Metal Service at SuNPe can help. We have well-equipped workshops and professional team to support production, and we can provide comprehensive services from post-machining to surface finishing and various metal materials to satisfy your needs. We can use steel mold to produce low-volume parts fast, with mold and post machining, we are able to achieve complex shapes and features as designed. Our Sheet Metal Fabrication is typically used for production of automotive parts, mechanical assemblies, electrical pieces and so on.

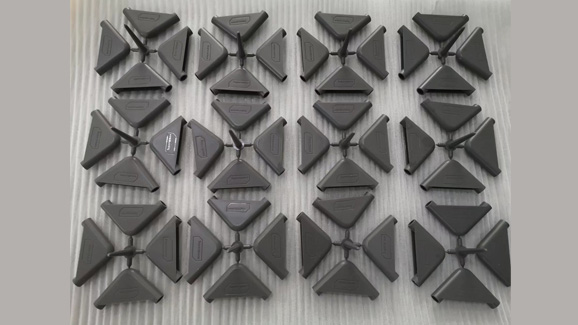

Low Volume Vacuum Casting

Vacuum Casting is also called PU Casting or Urethane Casting. PU Casting at SuNPe is a great option for 10-50 plastic pieces. We have total 4 workshops with 10 sets machines to support, and we can provide all kinds of PU materials for different parts. With silicone mold, we can provide over-molding and achieve the parts with desired color and texture fast. We typically use this Urethane Casting to produce low-volume functional parts like key pads, rubber buttons and more.

Low Volume Plastic Injection Molding

Injection Molding at SuNPe is preferred for low volume production of plastic parts. We have complete factories with advanced CNC machines and injection equipments to support plastic production; we typically can make the steel molds then copy range from 50 to over 100,000 parts fast, and we can use same mold for those different parts have same shape or features to save the timing and costs. We can provide various plastic materials, flexibility for color and texture, surface finishing and assembly to achieve your request.

Low Volume Pressure Die Casting

Pressure Die Casting at SuNPe can help metal production. We can make tens of thousands of metal pars with perfect finish fast through building steel molds with long service life, we can achieve good precision for metal parts by post machining, and we provide services from post machining to surface finishing. We typically use aluminum, zinc and magnesium for die casting.