Pressure Die casting

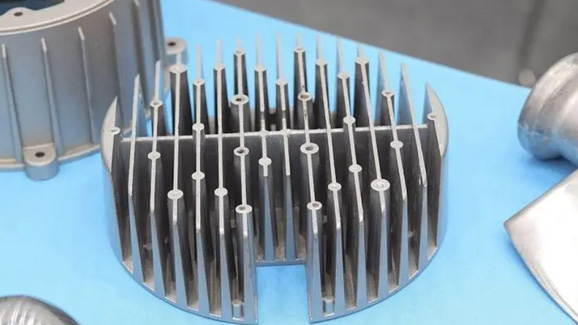

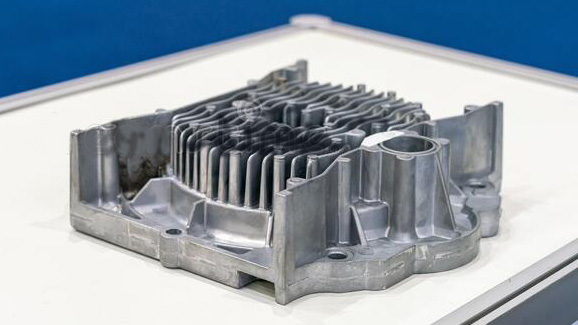

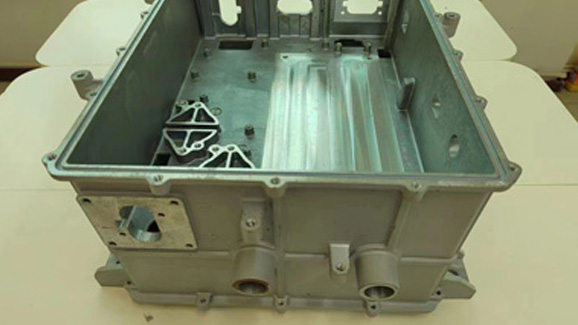

Aluminum die casting Multiple materials options

Zinc die casting No MOQ; Strict quality system

Magnesium die casting Great secondary operations capacity

Pressure Die Casting Service at SuNPe

What is pressure die casting?

Pressure die casting is an efficient manufacturing method for producing metal components , which is use high-intensity pressure and speed to forces the molten metal into a closed steel die cavity. It is suitable for high volume production projects. SuNpe can offer metal die casting service for prototype, low-volume and series production projects.

What industries die casting apply in?

Die casting is widely used in various industries, such as automotive, consumer, medicalmedical and industrial products. At SuNPe, we have rich experience with manufacturing car lamps housing components, car heat sink components, consumer products etc.