Injection Molding for Panel of Endoscope Device

- designer:

- Types:

- Craft:

- time:2024-04-13 08:02:52

- Pageviews: time

- Service Content:SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different materials, tool making, part fabrication, finishing, and final inspection.

- Preview:View

SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different ma

Injection Molding for Panel of Endoscope Device

Overview:

SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different ma...

One Stop Service for Panel of Endoscope Device Project

Service: Injection, Surface finish (EMI coating/Silk-screen printing) , Assembly, Packing and Delivery

Material: PC

Quantity: 100 pcs

Lead time: 33 days

Tooling manufacture: 25 working days

Injection molding for 100pcs: 2 working days

EMI coating: 3 working days

Silk-screen printing: 2 working days

Assembly and packing: 1 working day

SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different materials, tool making, part fabrication, finishing, and final inspection.

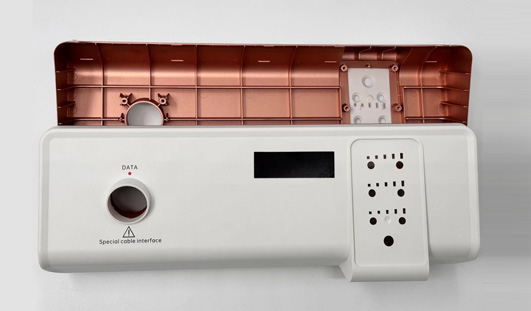

Here we will show you a case of an endoscope front panel made by injection molding.

Inspection:

2)And EMI coating is applied on the inner surface, the unspecified surfaces must be masked well before doing the EMI coating.

Checking the EMI coating to make sure it meets the spec:

3)Assembly Inspection to make sure the Key thin film no warping issue:

We will send FAI samples to our customers for review after the tooling is finished, and will not go into production run until we get approval from customers.

SuNPe provides one stop on demand services for medical industry, we have been manufacturing many medical metal or nonmetal products from prototyping to production such as lab instruments, medical accessories, shells, bracket, plug, test box and so on, demonstrating our capabilities including CNC, sheet metal, vacuum casting, injection molding, and different surface finishing.

Please click here to learn more: https://sunpe.com/medical-devices.html

And if you have any projects or questions about medical products like this, welcome to contact us! We are on standby for any further discussion.

Service: Injection, Surface finish (EMI coating/Silk-screen printing) , Assembly, Packing and Delivery

Material: PC

Quantity: 100 pcs

Lead time: 33 days

Tooling manufacture: 25 working days

Injection molding for 100pcs: 2 working days

EMI coating: 3 working days

Silk-screen printing: 2 working days

Assembly and packing: 1 working day

SuNPe have done Custom plastic injection molding projects for various industries including medical, automotive, electronics, consumer products with more than 10 years of experience, we can offer a complete solution that covers every aspect of different materials, tool making, part fabrication, finishing, and final inspection.

Here we will show you a case of an endoscope front panel made by injection molding.

1.DFM Discussion before making the tooling:

We had a meeting with our customer to discuss our DFM, and make improvements after learning more about customer’s demand. After receiving the approval, we started to make the tooling.

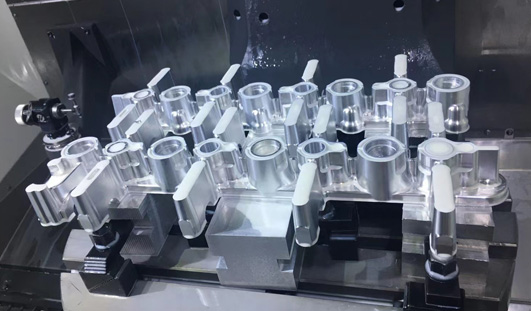

2.Tooling manufacturing:

We made an insert for the top hole for machining in case that we could correct the deviation more easily, sliders and lifters are used to make the side holes.

3.Finishing and inspection:

1)This part is required to do silk-screen printing for text and icons:

Inspection:

2)And EMI coating is applied on the inner surface, the unspecified surfaces must be masked well before doing the EMI coating.

Checking the EMI coating to make sure it meets the spec:

3)Assembly Inspection to make sure the Key thin film no warping issue:

We will send FAI samples to our customers for review after the tooling is finished, and will not go into production run until we get approval from customers.

SuNPe's capabilities for medical products:

SuNPe provides one stop on demand services for medical industry, we have been manufacturing many medical metal or nonmetal products from prototyping to production such as lab instruments, medical accessories, shells, bracket, plug, test box and so on, demonstrating our capabilities including CNC, sheet metal, vacuum casting, injection molding, and different surface finishing.

Please click here to learn more: https://sunpe.com/medical-devices.html

And if you have any projects or questions about medical products like this, welcome to contact us! We are on standby for any further discussion.