1.What is EMI coating?

EMI coating, also called conductive paint. Conductive paint is a kind of paint film formed after drying, which can play the role of conductive spray coating, thereby shielding the function of electromagnetic wave interference. In order to improve the conductivity of coatings, conductive coatings are usually made by adding metal powders such as copper, nickel or silver to specific resin raw materials as conductive particles.2.What is EMI coating main applications?

EMI coatings are materials designed to contain, shield or control electric fields to prevent undesired responses or performance degradation in electronic enclosures. EMI coatings are used in medical equipment, military, telecommunications, automotive, consumer goods, instrumentation, communications products, computers, portable electronics, network hardware, home electronics, aerospace and defense and other electronic equipment industries.3.What conductive filler can be used for the EMI coating?

There are many types of conductive filler used for EMI coatings. Conductive fillers are a decisive factor in EMI coating. At present, EMI coating can be divided into nickel-based, copper-based, silver-based, carbon-based coatings and composite conductive paint according to the types of fillers.3.1Nickel-based conductive paint

Nickel-based conductive paint have good shielding effect, moderate price and good oxidation resistance, and are the mainstream of EMI coating research.3.2Copper-based conductive paint

Copper-based conductive paint have good electrical conductivity, but poor oxidation resistance and unstable performance. The key technical problem of water-soluble copper conductive paint is to prevent the water in the paint from oxidizing the copper powder, resulting in a decrease in its conductivity. Add complex organic antioxidants to coatings.3.3Silver-based conductive paint

Silver-based conductive paint, also known as conductive silver paste (Silver Paste), is mainly composed of silver and resin, with high conductivity. It can be used as a special material for sun protection and UV protection on parasols. Usually, the silver paint on the parasol is to resist UV rays and improve the performance of the parasol. Due to its high conductivity, it can also be used in the fabrication of printed circuit boards.3.4Carbon-based conductive paint

For carbon-based conductive paint such as graphite and carbon black, the conductivity is relatively poor, and the effect of being used as an electromagnetic shielding material is worse than that of other metal fillers. However, carbon-based paint have the advantages of good environmental resistance, high density and low price.3.5Composite conductive paint

In recent years, composite conductive paint have attracted attention due to their low cost and high electrical conductivity. A nanocomposite electromagnetic wave absorbing paint was prepared with carbon-coated iron (Fe/C) nanoparticles as filler and water-based acrylic resin as base material. The nanoparticles were modified with sodium dodecylbenzenesulfonate to improve the dispersibility of the nanoparticles in the matrix. The prepared paint has good electromagnetic wave absorbing properties.4.What EMI coating services offer at SuNPe ?

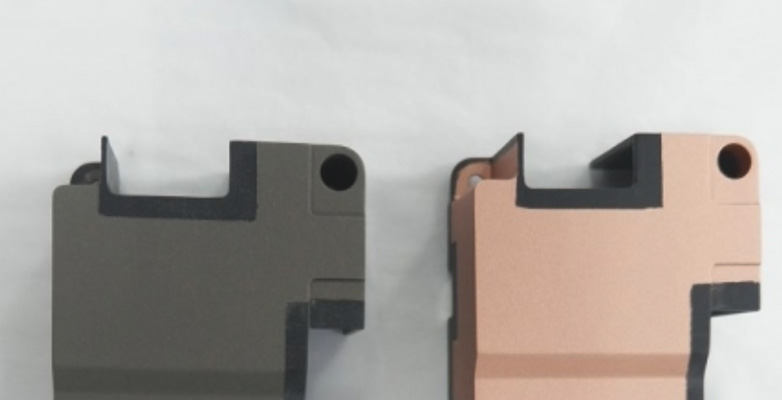

At SuNPe, nickel-based conductive paint and copper-based conductive paint are widely used on products because they are much cheaper than conductive paint of other materials and have better conductive properties. Traditionally, electronic circuits were housed in metal boxes to provide shielding by cutting off the transmission path of electromagnetic energy. Today, more and more plastic enclosures are being used to reduce weight and cost. Plastic enclosures are transparent to electromagnetic interference, so sensitive components are in an unprotected state. To protect the sensitive components, we usually add a layer of EMI coating on the plastic case, such as PC, PC + ABS, ABS material case. The following two pictures are the pictures of nickel-based conductive paint and copper-based conductive paint plastic products we made for our client for reference.

(nickel-based conductive paint and copper-based conductive paint products)

5.What is the technical parameters for EMI coating ?

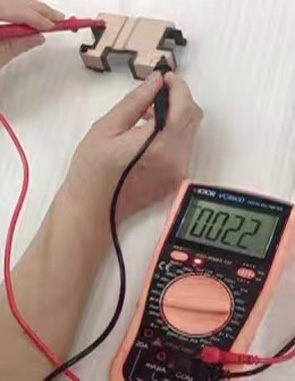

Conductive effect: ≤0.025 ohm/cm2 (film thickness of not less than 20 microns)Application conductivity parameters: 1 ohm / 20 microns film thickness / distance 10cm

Recommended film thickness: 20-25 microns (ASTMD4138-94)

(Numerical measurement of conductive paint resistance)

Other news

- 1Anti-dust painting room at SuNPe

- 2SuNPe Has Strict Packaging Requirements

- 3The First Shipment After The Labour Holiday!

- 4Keep Moving, Keep Thriving--SuNPe's Sales Team Activity in Hailing Island

- 5SuNPe Organized 2019 Charity Activity --- Grow with Love, grow with SuNPe

- 6More large-ton advanced injection molding machines arrived at SuNPe

- 7Environmental Hiking Through the Nature Protection Zone of East Dongting Lake

- 8UV Coating at SuNPe

- 9New Year Celebration——Sales Team of SuNPe

- 10Safety Meeting and Fire Drill at Plant 2 of SuNPe