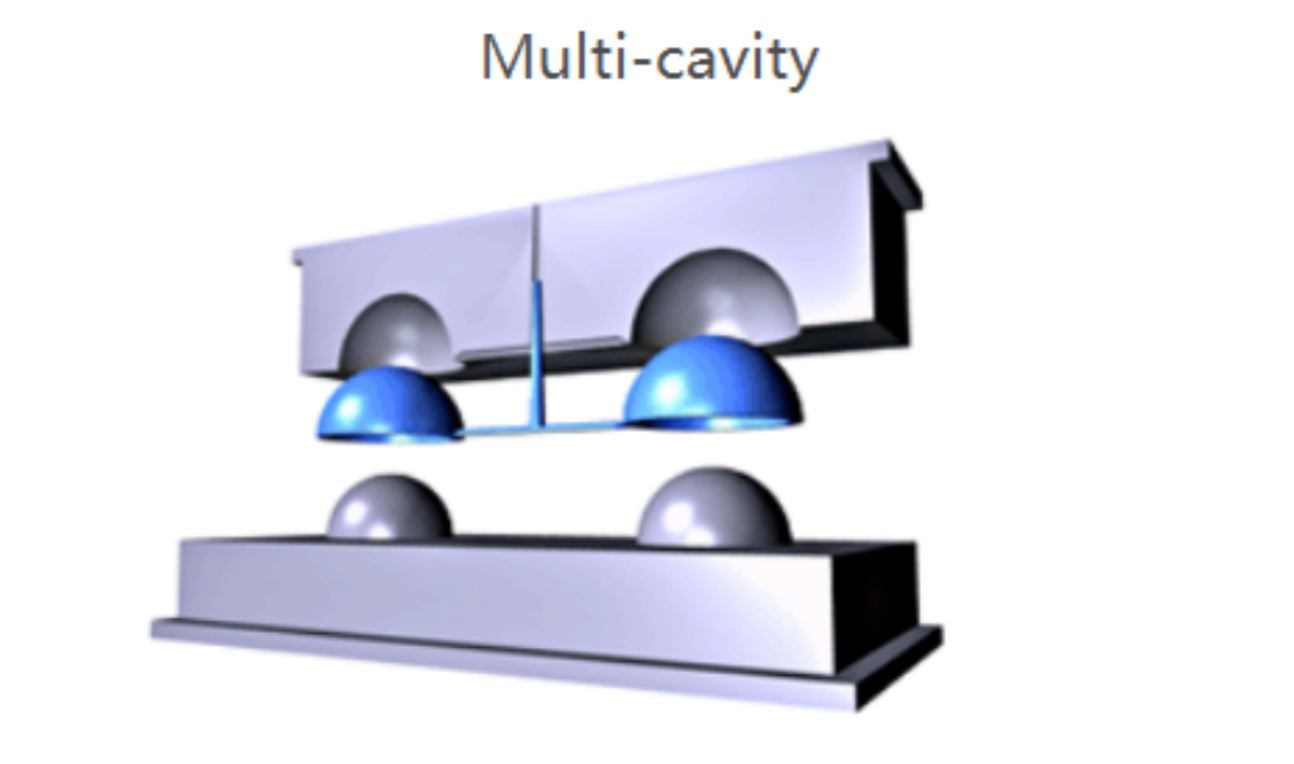

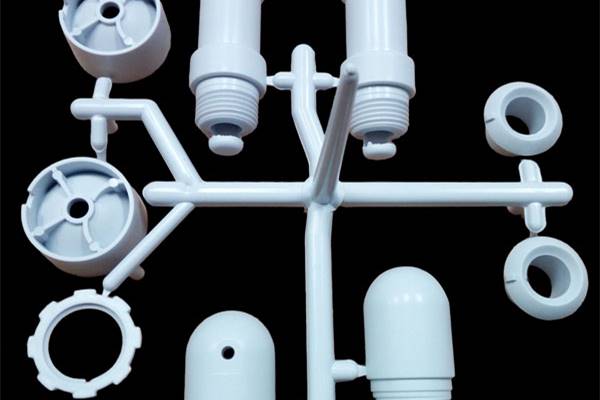

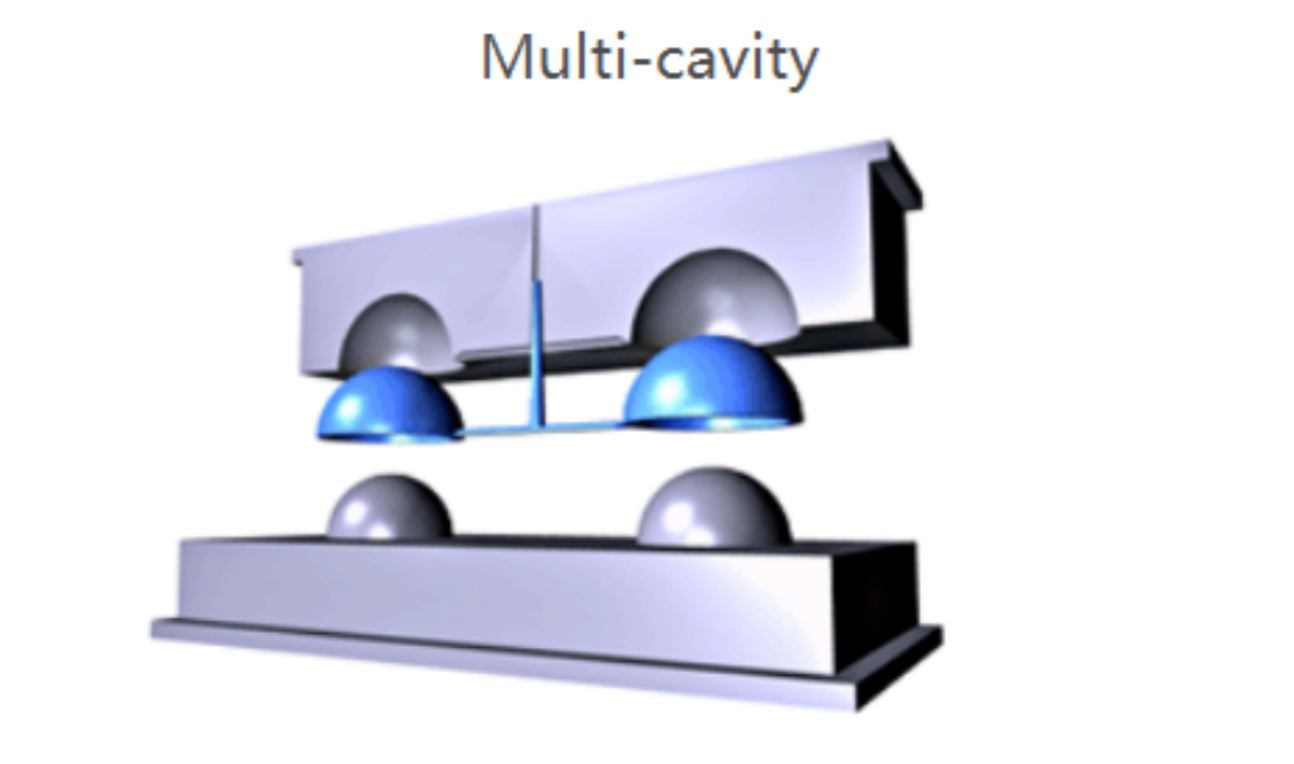

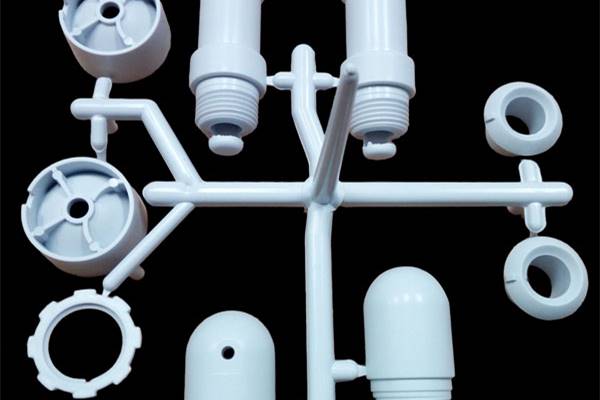

Family mould has more than one cavity of a set of parts,and it produces more than one part per production cycle. It also allow you to make more efficient use of the cycle time and produce more parts from the same mold within the shot guarantee.

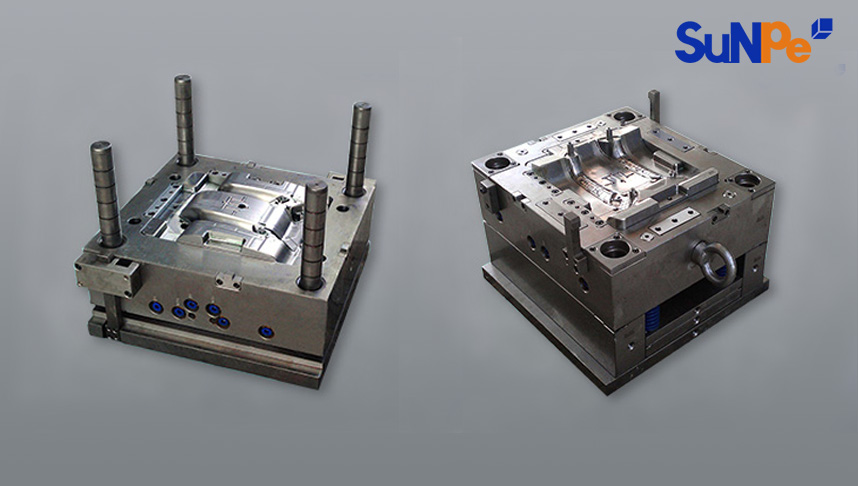

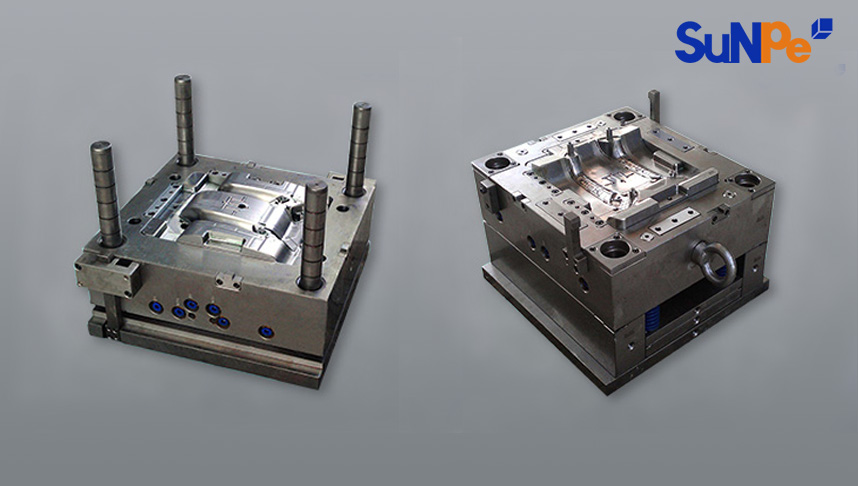

For tooling and injection molding projects,in order to reduce cost and expedite the time,at SuNPe, for tooling projects, we can help to reduce the cost by use family mold.

The benefit of family mould:

1.Save mould cost. By use family mould,a set of parts can share one mould,which can reduce the mould cost.

2.Fast molding cycles. By using family mould,we can produce more than one parts per production cycle,which can expedite the molding cycles.

3.Ideal for prototype molds. For rapid tooling projects,using family mold can reduce the cost and time,which is very helpful for the prototype molds.

At SuNPe, we have three independent mold and injection workshops, with more than 16 years experience, we will analyze your projects before production to find the best way to production. For your tooling project,in order to reduce the cost and time,for the similar size parts, family mould is always the first choice. Furthermore, for different material parts,we also can use movable sprue to realize family mould.

In additional,for tooling and injection molding,we also will use soft tool, share the mould base, and consider hand loading insertion or post-machining to simplify the complex tooling structure to help our customer reduce the cost and save time.

For tooling and injection molding projects,in order to reduce cost and expedite the time,at SuNPe, for tooling projects, we can help to reduce the cost by use family mold.

The benefit of family mould:

1.Save mould cost. By use family mould,a set of parts can share one mould,which can reduce the mould cost.

2.Fast molding cycles. By using family mould,we can produce more than one parts per production cycle,which can expedite the molding cycles.

3.Ideal for prototype molds. For rapid tooling projects,using family mold can reduce the cost and time,which is very helpful for the prototype molds.

At SuNPe, we have three independent mold and injection workshops, with more than 16 years experience, we will analyze your projects before production to find the best way to production. For your tooling project,in order to reduce the cost and time,for the similar size parts, family mould is always the first choice. Furthermore, for different material parts,we also can use movable sprue to realize family mould.

In additional,for tooling and injection molding,we also will use soft tool, share the mould base, and consider hand loading insertion or post-machining to simplify the complex tooling structure to help our customer reduce the cost and save time.

Other news

- 1SuNPe Organized 2019 Charity Activity --- Grow with Love, grow with SuNPe

- 2How many polishing methods in the surface finishing?

- 3SuNPe Organized 2018 Campus Commonweal Activities --Hand in hand, for love

- 4The 2017 Friendly Basketball Match for HuiZhou Commercial Union of ZhongShan

- 5Keep Moving, Keep Thriving--SuNPe's Sales Team Activity in Hailing Island

- 6New times new start party at SuNPe

- 7Internal Regular Quality Review Meeting of SuNPe

- 8SuNPe –Professional and Reliable Injection Molding Company

- 9Self-Challenge, Self-Improvement

- 10Environmental Hiking Through the Nature Protection Zone of East Dongting Lake