SuNPe is a professional machining manufacture. What is Spline and what types of Spline does SuNPe can do for you? Let's learn from this article.

A spline connection consists of an inner and an outer spline. Both internal and external splines are multi-tooth parts, the spline on the inner cylinder surface is the internal spline, and the spline on the outer cylinder surface is the external spline. Splines are generally used when both linear and rotational motion is desired. There are various types of splines used for numerous industrial applications.

(inner and outer spline,various types of splines)

There are 3 types spline SuNPe can do for you:

This type has equally spaced teeth that are straight sided. It's easy to process, grinding method can be used to achieve higher accuracy. But spline broaches are usually used and unable to process no thru hole's spline. For the no thru hole's spline, it only can use slotting processing, but the accuracy is low.

(Parallel Spline,equally spaced teeth)

This type has equally spaced teeth, but they are not straight sided. The tooth pro profile is involute. The teeth do not have the same proportions as a gear tooth, they are shorter in height. The processing is the same as gear. It's easy to achieve high precision and interchangeability This type's spline is widely used.

(Involute Spline)

These splines are the inner spline tooth shape is triangular. The pressure angle is equal to 45°of involute. This type of spline is easy to process. Tiny teeth and more that it's easy to adjust and assemble. Mainly used for light load and small diameter static connection, especially suitable for shaft and thin wall parts connection.

(Triangular Spline,inner spline tooth shape is triangular,shaft and thin wall parts connection)

(national spline standards)

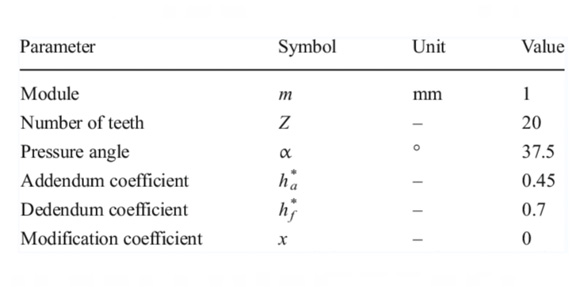

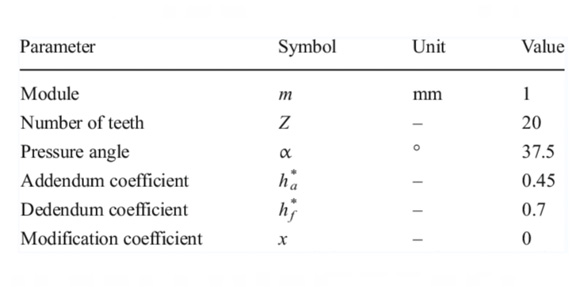

Before manufacturing, how to design your Spline and what parameter you need to provide to us? Below chart show you about the parameter for reference.

(Spline parameters,Design Spline,Spline Parameter)

Contact SuNPe to let us know your ideas and provide you with the best solutions.

E-mail: Sales@sunpe.com

What is Spline?

A spline connection consists of an inner and an outer spline. Both internal and external splines are multi-tooth parts, the spline on the inner cylinder surface is the internal spline, and the spline on the outer cylinder surface is the external spline. Splines are generally used when both linear and rotational motion is desired. There are various types of splines used for numerous industrial applications.

(inner and outer spline,various types of splines)

Types of Spline Shaft:

There are 3 types spline SuNPe can do for you:

(1)Parallel Spline

This type has equally spaced teeth that are straight sided. It's easy to process, grinding method can be used to achieve higher accuracy. But spline broaches are usually used and unable to process no thru hole's spline. For the no thru hole's spline, it only can use slotting processing, but the accuracy is low.

(Parallel Spline,equally spaced teeth)

(2)Involute Spline

This type has equally spaced teeth, but they are not straight sided. The tooth pro profile is involute. The teeth do not have the same proportions as a gear tooth, they are shorter in height. The processing is the same as gear. It's easy to achieve high precision and interchangeability This type's spline is widely used.

(Involute Spline)

(3)Triangular Spline

These splines are the inner spline tooth shape is triangular. The pressure angle is equal to 45°of involute. This type of spline is easy to process. Tiny teeth and more that it's easy to adjust and assemble. Mainly used for light load and small diameter static connection, especially suitable for shaft and thin wall parts connection.

(Triangular Spline,inner spline tooth shape is triangular,shaft and thin wall parts connection)

Here are the national standards:

| TYPE/Country Standard | Parallel Spline | Involute Spline | Triangular Spline |

| China | GB1144-87 | GB/T3478.1-1999 | / |

| Japan | JIS B1601-85 | JIS B1602-1992/ JIS D2001-1997 |

JIS B1602-1991 |

| Germany | SN742 | DIN 5480/ DIN 5482 |

DIN 5481 |

| The United States | Six slot rectangle spline standard by WEAN American Company | AN-SIB92.1a |

Spline parameters:

Before manufacturing, how to design your Spline and what parameter you need to provide to us? Below chart show you about the parameter for reference.

(Spline parameters,Design Spline,Spline Parameter)

Contact SuNPe to let us know your ideas and provide you with the best solutions.

E-mail: Sales@sunpe.com

Other news

- 1SuNPe Group Pays Tribute To Academician Yuan Longping

- 2SuNPe's Work Resumption During the COVID-19

- 3What is the Welding Process?

- 4Award of Merit for School Development Support

- 5How to Custom-Made a whole Unique Wheel at SuNPe?

- 6Amazing 3D Printing Project for Senturionkey's Luxury Exhibition Hall

- 7SuNPe Had a Successful Exhibition on Formnext 2018

- 8SuNPe Has Strict Packaging Requirements

- 9Competition promotes progress!

- 10Rapid tooling and Die Casting in SuNPe