Using metal wire to cut the metal shape that is called Wire Cutting (Electrical Discharge Machining). This machining process is available at SuNPe, and it is typically applied to machine steel mold, metal parts with complex shape or features, high hardness metal pieces and more.

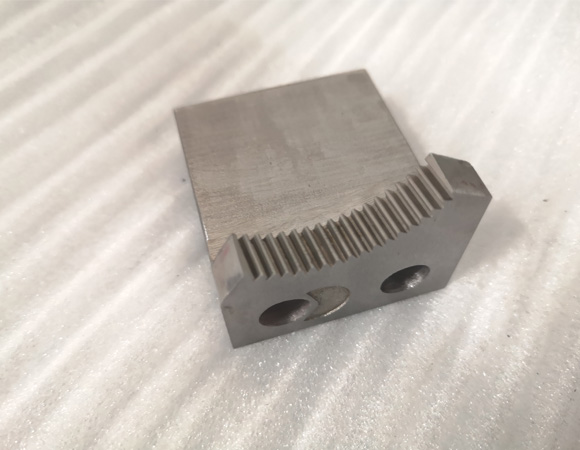

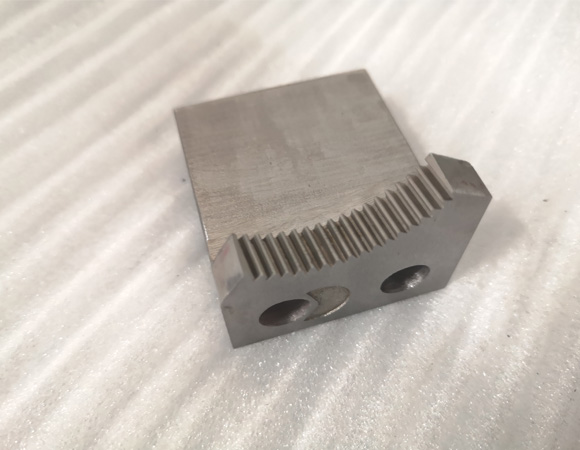

The Slider of Steel Mold:the main body of slider was machined by CNC process, but the intensive feature as shown can't be done by the knife tool of CNC, it was finished by wire cutting. We can use metal wire to cut the feature easily and reach consistent space.

(slider of tooling, Wire Cutting, CNC Machining)

Assembled parts: We noted that oblong part and stick require fine precision and they need to be fitted well without any large clearance between them, so we used wire cutting to make “T” groove for oblong part, and cut the whole shape for the stick to make each side straight, we are able to make them and remain tight tolerance for perfect assembly.

(lifter of tooling, assembly, fine precision, Wire Cutting)

Benefits:

1.Wire cutting can be applied to various conductive metal material

2.Reach fine precision

3.Achieve complex structure and features

4.Perfect natural finish without any burrs

5.Reduce material damage

The Slider of Steel Mold:the main body of slider was machined by CNC process, but the intensive feature as shown can't be done by the knife tool of CNC, it was finished by wire cutting. We can use metal wire to cut the feature easily and reach consistent space.

(slider of tooling, Wire Cutting, CNC Machining)

Assembled parts: We noted that oblong part and stick require fine precision and they need to be fitted well without any large clearance between them, so we used wire cutting to make “T” groove for oblong part, and cut the whole shape for the stick to make each side straight, we are able to make them and remain tight tolerance for perfect assembly.

(lifter of tooling, assembly, fine precision, Wire Cutting)

Benefits:

1.Wire cutting can be applied to various conductive metal material

2.Reach fine precision

3.Achieve complex structure and features

4.Perfect natural finish without any burrs

5.Reduce material damage

Other news

- 1Drager X-Act 7000 project at SuNPe

- 25 Types of Metal materials for Prototyping and Production

- 3Sheet metal prototype process flow at SuNPe

- 4What Makes SuNPe Be Outstanding In Quality Control?

- 5Safety Meeting and Fire Drill at Plant 2 of SuNPe

- 6SantaClaus appeared in SuNPe,come and see where we found him

- 7Factory Review under COVID-19

- 8SuNPe Holds Weekly PK Competition In Production Workshop

- 9SuNPe Organized 2019 Charity Activity --- Grow with Love, grow with SuNPe

- 10Excited moment! SuNPe celebrates for Annual Party in 2019.