What is post-machining?

Post-machining is where raw material or a component is taken for further working, usually involving material removal, and is carried out after a primary forming process. SuNPe usually use post-machining to meet key requirements of 3D printing, vacuum casting, die casting, metal casting and vacuum forming projects.Where does SuNPe use post-machining?

SuNPe widely use post-machining in following projects to meet key requirements:1. Post-machining for 3D printing projects

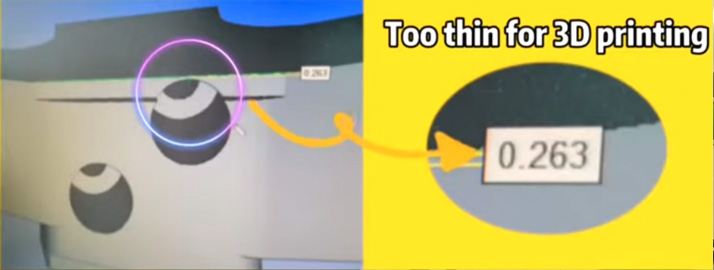

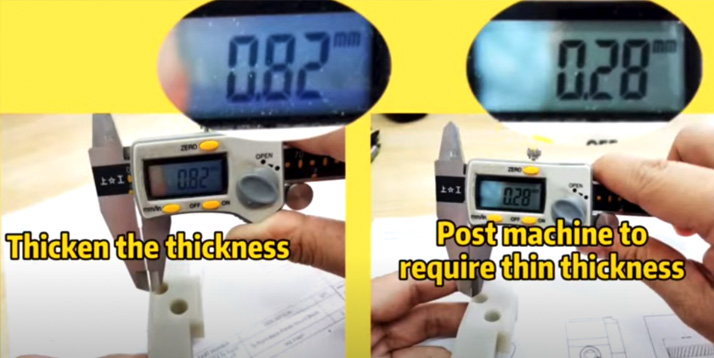

The wall thickness is too thin for 3D printing, we can thicken the wall thickness for 3D printing and then pos-machining to remove materials and hit the thin thickness.

(Post-machining for 3D printing parts,3D printing prototyping, 3D printing low volume production)

2. Post-machining for vacuum casting projects

As we know, vacuum casting use a soft silicone tooling to casting parts, it's hard to control the critical tolerance when casting, then post machining is needed.

3. Post-machining for die casting projects

Usually, the gates and slag of die casting parts are too thick to remove by hand, post-machining to remove the gates and slag to get a beautiful surface.

(Post-machining for die casting parts,die casting prototyping, die casting low volume production)

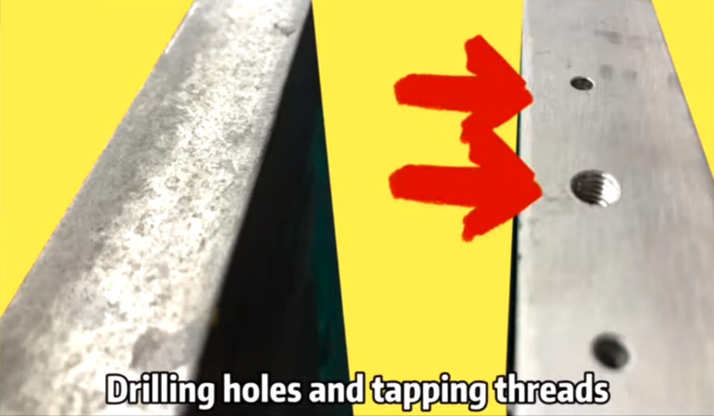

Drilling holes and tapping threads after die casting

(Post-machining for die casting parts,post-machining drill holes and tap threads)

Post-machining the sharp edges for fitting purpose

(Post-machining for die casting parts,Post-machining the sharp edges)

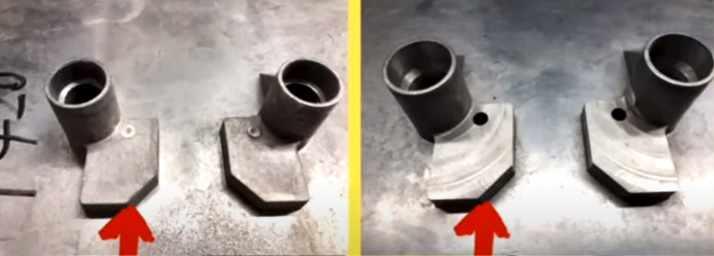

4. Post-machining for metal casting projects

Metal casting parts' surfaces are a little rough, post-machining to make surfaces bright and good for assembly.

(Post-machining for metal casting parts,Post-machining to get bright surfaces and good for assembly.)

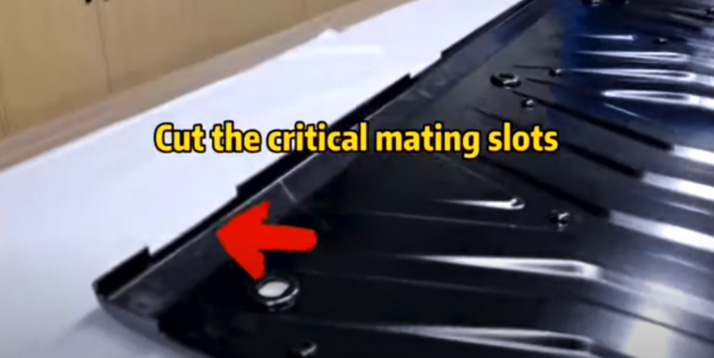

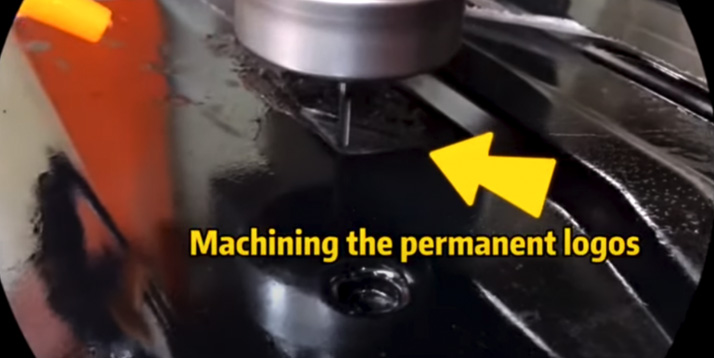

5. Post-machining for vacuum forming projects

Vacuum forming parts is made from a whole piece material, post-machining is used for cutting critical mating slots, holes and permanent logos on the outer surfaces

(Post-machining for vacuum forming parts,post-machining to cutting critical mating slots)

(Post-machining for vacuum forming parts,post-machining to permanent logos)

Huge CNC machining workshops to support post-machining at SuNPe

SuNPe owns more than 200 sets of CNC machines to support all kinds of projects, if you'd like to know more about post-machining and our other services, please feel free to contact us.

(CNC workshops, CNC workshops support post-machining, CNC prototype, CNC low volume production)

Other news

- 1How to solve the deformation of your prototype and low volume products?

- 2Operation of SuNPe Under COVID-19

- 3Vapor Polishing at SuNPe

- 4Do you know that SuNPe can provide ultrasonic welding service?

- 5SuNPe Wishes You A Happy Chinese New Year In 2021

- 6SuNPe successfully held the second basketball league

- 7SuNPe -Texture Code and Vacuum Casting material Card

- 8Celebrating The International Women's Day With SuNPe

- 9The Second Amateur Football Match of Zhongshan North District in 2017

- 10New Plant, New Production Capacity of SuNPe