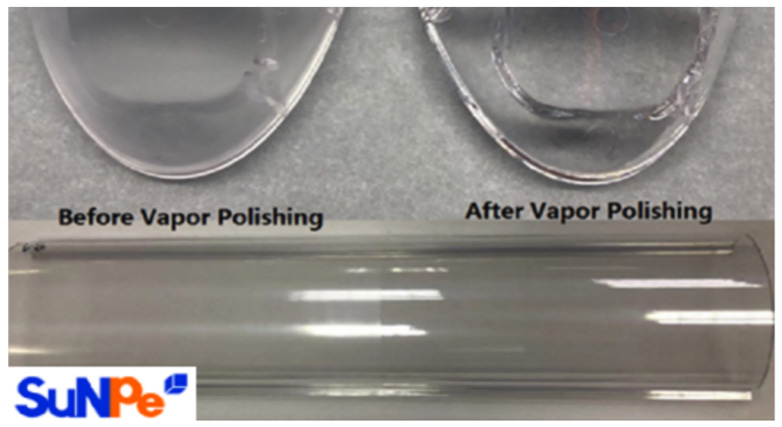

What is Vapor Polishing?

Vapor polishing is a method of polishing plastics to reduce the surface roughness or improve clarity. Typically, a component is exposed to a chemical vapor causing the surface to flow thereby improving the surface finish. This method of polishing is frequently used to return clear materials to an optical quality finish after machining. Vapor polishing works well in the internal features of components.

How to do vapor polishing?

1.Get CNC machining/Injection molding/ extruded parts

2.Sanding parts

3.Heat trichloromethane in electric stove to boiling point.

4.Spray the vapor on the surface of the part.

5.Get the clear parts.

2.Sanding parts

3.Heat trichloromethane in electric stove to boiling point.

4.Spray the vapor on the surface of the part.

5.Get the clear parts.

(CNC machining)

Surface finish ability)

(Electric stove used by SuNPe for vapor polishing)

(Vapor polishing)

Why need to sand the part before vapor polishing?

Vapor polishing works at the molecular level, there are machined, tooling marks on part's surface after CNC machining, injection molding and extrusion which cannot be removed by Vapor polishing. Sanding can remove these marks and we can get clearer parts after vapor polishing.

What material available for vapor polishing?

Clear ABS and Clear PC perform great after vapor polishing.

Injection molding parts, extruded parts, CNC machining parts can be vapor polished to improve transparency at SuNPe.

How fast to do vapor polishing?

Vapor polishing is a fast process with a quick lead-time, It only takes a few seconds to complete a piece.

Compared to the cost of polishing by hand and machine polishing, vapor polishing is very cost-effective.

Can small holes or small features be polished to provide transparency?

Yes, any holes, recesses, raised and other features that cannot be polished by hand or machine can be vapor polished to improve transparency in few second at SuNPe.

What quantity can do vapor polishing at SuNPe?

SuNPe can do vapor polishing from prototype to low volume quantity parts, SuNPe can even serve 1 piece.

Advantages of Vapor Polishing

● Quick lead-time and efficient

● Reduce cost

● Improves optical clarity of materials

● Reduce cost

● Improves optical clarity of materials

In addition to vapor polishing, we also have other excellent surface finish services, such as Sandblasting, Painting, Anodizing, Chrome Plating, Powder Coating, Brush finish, E-coating, Logo Printing, etc.

Please feel free to contact us to know about surface finish for your next project.

Other news

- 1New Plant, New Images of SuNPe

- 2SuNPe Attaches Great Importance To Product Quality And After-Sales Service

- 3SuNPe Helps New Energy Vehicle project by CNC machining

- 4How to solve the deformation of your prototype and low volume products?

- 5Award of Merit for School Development Support

- 65 Types of Metal materials for Prototyping and Production

- 7Interchangeable inserts for Injection Molding Project

- 8How does SuNPe help with surface texture?

- 9Award of Merit for School Development Support

- 10Better service, Better you—Amazing activity at SuNPe