5 Types of Metal materials for Prototyping and Production

5 Types of Metal materials for Prototyping and Production

In our daily life, metal made products are everywhere. But do you know the properties of metals and the reason for their special use?

Today, we are going to learn some interesting knowledge about metal, there are 5 types metal materials you should know:

At SuNPe, Aluminum materials are generally processed by CNC machining, 3D printing, die casting and so on, which could meet your requirement from prototyping to low volume production, and it is commonly used in automobile products, industrial equipment prototype products etc.

We have managed the medical devices prototype project with customized Tungsten steel nickel alloy, due to the hardness characteristic of Tungsten steel nickel alloy, it is not as easy to work as usual aluminum, stainless steel and other materials, so we finally processed via Grinding, Wire cutting and EDM with special tools.

The common tungsten alloy products in our daily life likeX-ray anodes, anti-scattering plates, radioactive containers, adiation protection and medical shielding components etc.

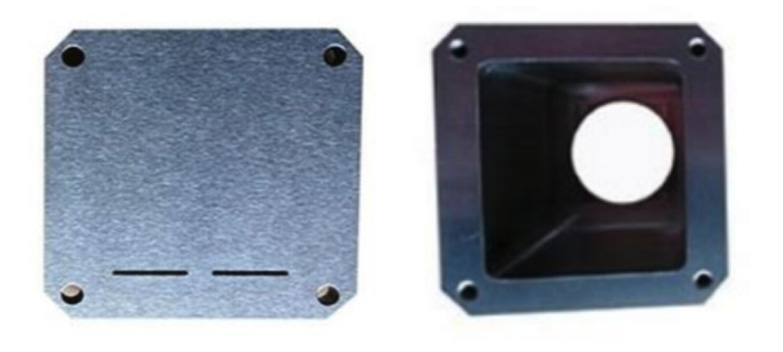

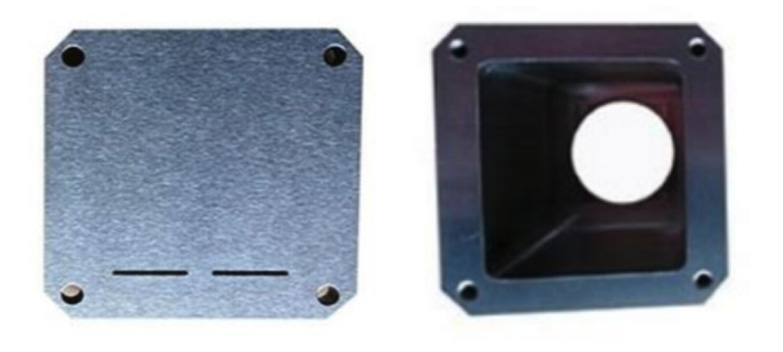

(Customized Tungsten-nickel-iron alloy, nuclear medical shielding components, Grinding, Wire cutting and EDM)

Niobium: It deteriorates into a superconductor with almost no resistance when cooled to an ultra-low temperature of 263.9℃.

Tantalum-niobium hard alloy have good thermal strength, thermal resistance and machining performance, so they are widely used in the manufacture of aircraft parts and gas turbine blades. At SuNPe, we have experience in machining low temperature components prototype with Niobium titanium superconducting alloy.

Titanium: Titanium is a gray transition metal, characterized by light weight, high strength, good corrosion resistance, is reputed as "Aerospace metal".

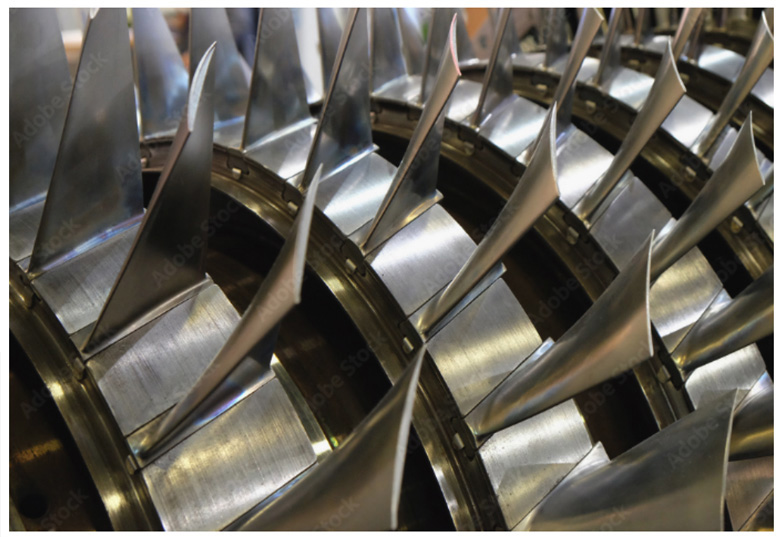

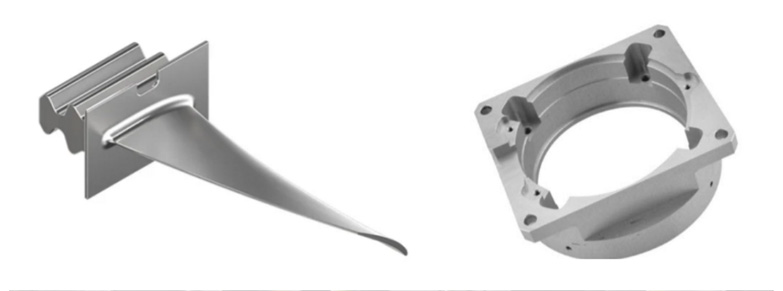

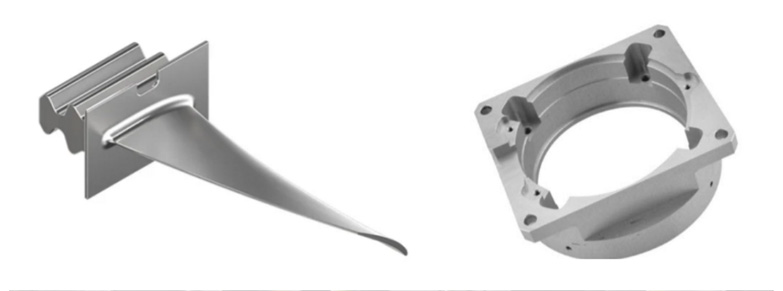

(Aerospace Turbine Blade, titanium part) (Aircraft Structural Part, titanium, CNC machining)

Tantalum: It does not react with hydrochloric acid, concentrated nitric acid and aqua regia under hot and cold conditions. With its excellent biocompatibility and stability, tantalum metal is also manufactured into various bone plates and other medical components.

If you are not sure about using which material for your specific requirement, you can discuss your projects or application with our team.

Today, we are going to learn some interesting knowledge about metal, there are 5 types metal materials you should know:

1)The most abundant metal in the world

Aluminum: its abundance is about 8% of the earth's crust so reserves are very rich, which determines that aluminum is widely used in industry and our daily life. Aluminum is a thermal conductor and well noted with good ductility and corrosion resistance.At SuNPe, Aluminum materials are generally processed by CNC machining, 3D printing, die casting and so on, which could meet your requirement from prototyping to low volume production, and it is commonly used in automobile products, industrial equipment prototype products etc.

2)The hardest metal to melt

Tungsten: Melting point 3410℃, boiling point 5700℃. Due to its high density, radiation shielding and vibration absorption characteristics, tungsten alloys are very suitable for medical applications. At SuNPe, we can not only offer standard tungsten materials, but also available in custom tungsten steel materials, such as: Tungsten steel + 10% nickel.We have managed the medical devices prototype project with customized Tungsten steel nickel alloy, due to the hardness characteristic of Tungsten steel nickel alloy, it is not as easy to work as usual aluminum, stainless steel and other materials, so we finally processed via Grinding, Wire cutting and EDM with special tools.

The common tungsten alloy products in our daily life likeX-ray anodes, anti-scattering plates, radioactive containers, adiation protection and medical shielding components etc.

(Customized Tungsten-nickel-iron alloy, nuclear medical shielding components, Grinding, Wire cutting and EDM)

3)The easiest superconducting element to use

Niobium: It deteriorates into a superconductor with almost no resistance when cooled to an ultra-low temperature of 263.9℃. Tantalum-niobium hard alloy have good thermal strength, thermal resistance and machining performance, so they are widely used in the manufacture of aircraft parts and gas turbine blades. At SuNPe, we have experience in machining low temperature components prototype with Niobium titanium superconducting alloy.

4) The most important metal in aerospace industry

Titanium: Titanium is a gray transition metal, characterized by light weight, high strength, good corrosion resistance, is reputed as "Aerospace metal".

(Aerospace Turbine Blade, titanium part) (Aircraft Structural Part, titanium, CNC machining)

5) The most acid-resistant metal

Tantalum: It does not react with hydrochloric acid, concentrated nitric acid and aqua regia under hot and cold conditions. With its excellent biocompatibility and stability, tantalum metal is also manufactured into various bone plates and other medical components.If you are not sure about using which material for your specific requirement, you can discuss your projects or application with our team.

Other news

- 1EMI coating service at SuNPe

- 2Two New Injection Molding Machines For Producing White and Transparent Components

- 3Award of Merit for School Development Support

- 4Plastic ultrasonic welding service at SuNPe.

- 5SuNPe Holds Weekly PK Competition In Production Workshop

- 6SuNPe Helps New Energy Vehicle project by CNC machining

- 7The Annual Sales Meeting and Badminton Activity

- 8Improve ourselves, improve our service -- training and developing of management

- 9The Safety Meeting and Fire Drill Activity at Headquarters of SuNPe

- 10SuNPe Wishes You A Happy Chinese New Year In 2021