What is over-molding?

Over-molding is a unique molding process that can combine multiple materials into a single part or product. It is commonly used to produce consumer electronics and industry equipments. SuNPe provides plastic overmold plastic, plastic overmold metal, rubber overmold plastic services for prototyping and production.

(Plastic and metal overmolding products)

What kinds of Over-molding can do at SuNPe?

The over-molding process produces chemically bonded parts made using various materials. Depending on the materials, we can make the following types of over-molding:● Plastic Over Plastic - The substrate is rigid plastic. Then another rigid plastic is molded onto or around the substrate. In this way, it can help to improve the ergonomics of a product, manufacture the product in different colors and resins.

(Different color plastics overmolding ; 2-shot molding parts; 2K injection molding;)

( Rubber overmold plastic; overmolding prototypes; overmolding for vacuum casting)

The first substrate is metal, then rigid plastic will be molded around the substrate. This is often used for insert installing, which also called inserts over-molding.

(Vacuum casting - insert molding) ( Injection molding - brass inserts over-molding)

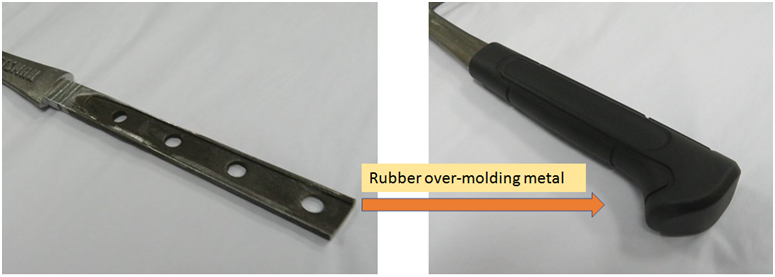

Compared with insert molding, the second plastic changed from rigid plastic to rubber. The first metal part can be produced by formed, CNC machining, die casting.

(Rubber overmold metal, overmolding silicone )

What technologies can SuNPe use to over-molding?

Vacuum Casting - When the product is in the premise research and development and testing stage, the number of required is not large, vacuum casting is the most affordable way to do over-molding, which is suitable for prototyping projects under 100 pieces.

Injection molding - For low-volume production and mass production projects, it has obvious benefits on time and cost, which can bring the products to the market in a short time.

Please feel free to contact us to know more about our overmolding service.

Other news

- 1SuNPe Organized 2019 Charity Activity --- Grow with Love, grow with SuNPe

- 2What is over-molding?

- 3SuNPe Helps New Energy Vehicle project by CNC machining

- 4Internal Regular Quality Review Meeting of SuNPe

- 5Environmental Hiking Through the Nature Protection Zone of East Dongting Lake

- 6SuNPe Sanya Team Building Trip 2020

- 7New Plant, New Images of SuNPe

- 8Formnext 2023 exhibition invitation from SuNPe Prototype at Booth 110-F37

- 9UV Coating at SuNPe

- 10What Makes SuNPe Be Outstanding In Quality Control?