Quick Quote

SuNPe

Our Services

SuNPe Our Services

We focus on prototyping, tooling & injection molding, finishing, low-volume production services and so on.

SuNPe

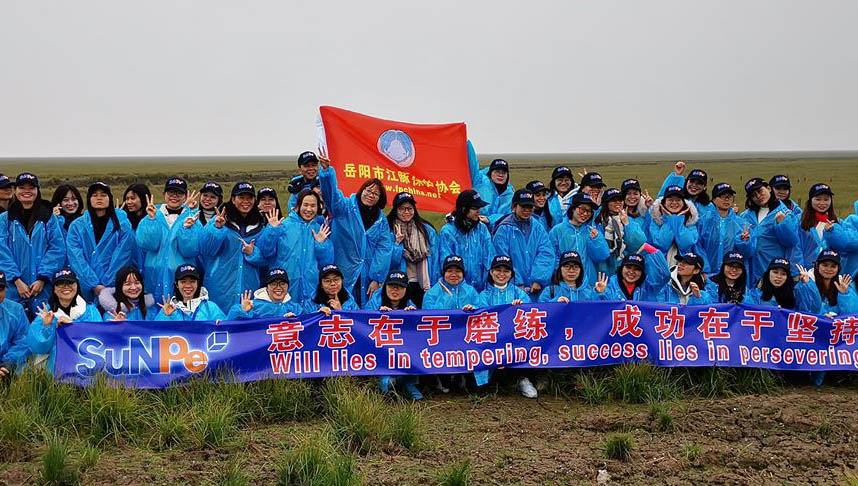

Visit our factories

SuNPe, Your Professional & Reliable Partner

We are an experienced prototyping and low-volume production company for your team. Watch our video to learn more about how SuNPe supports one-stop rapid prototyping services to help you at every stage of product development.

Visual Presentation Prototype

Functional & Testing Prototype

Low-Volume Production

SuNPe

Case Studies

SuNPe Case Studies

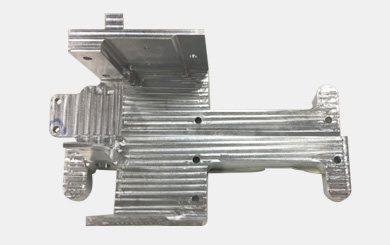

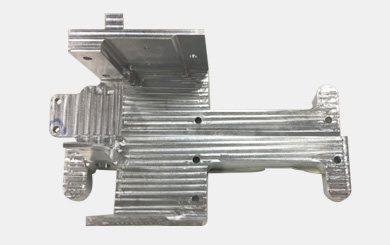

Our services mainly cover the area of automotive, home appliance, medical, electronic and industrial products, etc.We have many services can meet your demand, such as CNC machining, injection molding,die casting, vacuum casting and more. We can make all kinds of products for you, according to your design.

-

5-axis CNC Milling, Machined finish, More economical packing services. -

Quick turnaround to meet urgent timeline DFM provided in one day Tooling finished in 10 working days. 1000 products finished in 4-6 working days. -

Those who are familiar with SuNPe should know that we have rich experience in the fields of automotive, medical equipment and home appliances fields, but we also have a lot of experience in prototyping and low-volume production in other fields, such as the Soil Probe Project we are going to study now. -

SuNPe can combine multiple processes to make your unique design come to reality. -

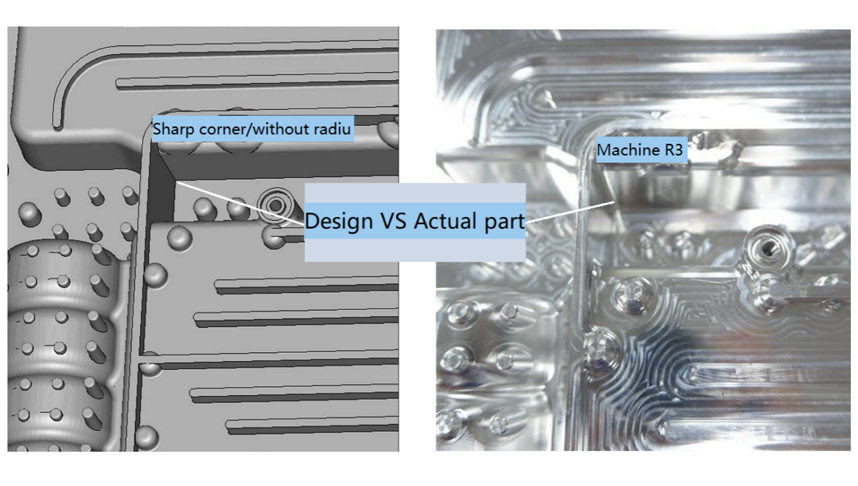

With professional techniques and huge capacity, we can help to handle and manage well the whole project for customers. Our customer work from one prototype to low volume from us for the fast lead time and cost effective.We send our quote within one day and send products in high quality in short lead time And we take good care of the drawing highlighted O-Ring groove “CNC to have best ability”,we can CNC Machine to achieve customer’s different surface roughness directly,no handwork needed and make sure of the assembly sealing requirements as request. -

At SuNPe, a gorgeous looking parts can be achieved by CNC machining and surface finishing, which is made of PMMA with dip dyeing and high mirror polishing. -

CNC machining, Laser cut&Sheet metal&Riveting, Vacuum casting, Lathe.Also supply fasteners, assemble, packaging and delivery. -

CNC, Die casting, Surface finish ( Powder coating matching the effect of bark) ,Assembly, Testing, Packing and Delivery